- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

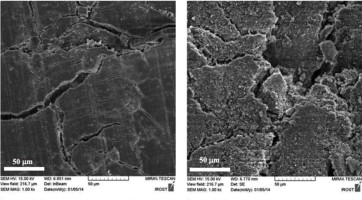

• Crushing strength of gamma alumina support was modeled using RSM to optimize support forming.

• The model was validated using analysis of variance.

• Reducing binder concentration and calcination temperature enhanced crushing strength.

• Reliable samples should have both high crushing strength and Weibull modulus.

The mechanical strength of solid catalysts is considered an important factor in terms of ensuring the reliable performance of industrial reactors. In this work, a pelletizing method was used to form gamma alumina support for catalysts. Response surface methodology (RSM) was employed to analyze and model the effects of various manufacturing parameters on the crushing strength of the supports. These parameters were binder concentration, compaction pressure, calcination temperature, and drying mode. The suggested model was verified by applying an analysis of variance to assess its validity with regard to crushing strength. The mechanical reliability of various supports was also determined by calculating their Weibull modulus values through linear regression of the Weibull equation. The material with the highest mechanical strength reliability will have both a high mean crushing strength and a high Weibull modulus, and the best values obtained for a support in this work were 70.7 MPa and 6.63, respectively. The conditions used to form this sample were: 20 mass% binder concentration, 861 MPa compaction pressure, 466 °C calcination temperature, and gentle drying.