- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

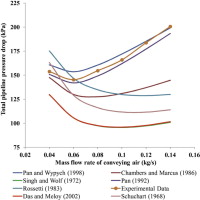

• Seven existing bend models for pneumatic conveying were evaluated.

• The models provided significantly varying bend loss predictions.

• Predictions of total pipeline conveying characteristics greatly depended on bend model selection.

• Some bend models underpredicted losses in dilute phase and overpredicted in dense phase.

An accurate estimation of the total pressure drop of a pipeline is important to the reliable design of a pneumatic conveying system. The present paper presents results from an investigation into the modelling of the pressure drop at a bend in the pneumatic conveying of fly ash. Seven existing bend models were used (in conjunction with solids friction models for horizontal and vertical straight pipes, and initial acceleration losses) to predict the total pipeline pressure drop in conveying fly ash (median particle diameter: 30 μm; particle density: 2300 kg/m3; loose-poured bulk density: 700 kg/m3) in three test rigs (pipelines with dimensions of 69 mm inner diameter (I.D.) × 168 m length; 105 mm I.D. × 168 m length; 69 mm I.D. × 554 m length). A comparison of the pneumatic conveying characteristics (PCC) predicted using the seven bend models and experimental results shows that the predicted total pipeline PCC and trends depend on the choice of bend model. While some models predict trends that agree with the experimental results, other models predicted greater bend pressure drops for the dense phase of fly ash than for the dilute phase. Models of Pan, R. (1992). Improving scale-up procedures for the design of pneumatic conveying systems. Doctoral dissertation, University of Wollongong, Australia, Pan, R., & Wypych, P.W. (1998). Dilute and dense phase pneumatic conveying of fly ash. In Proceedings of the sixth International Conference on Bulk Materials Storage and Transportation (pp. 183–189), Wollongong, NSW, Australia and Chambers, A.J., & Marcus, R.D. (1986). Pneumatic conveying calculations. In Proceedings of the second International Conference on Bulk Materials Storage and Transportation (pp. 49–52), Wollongong, Australia reliably predicted the bend losses for systems conveying fly ash over a large range of air flows.