- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

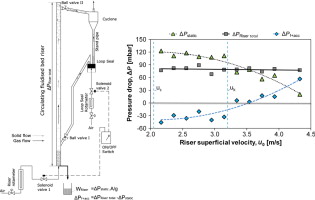

• Riser inventory calculated from the ΔPRiser may vary in reality due to friction.

• Quick closing valve method was used in CFB risers to find friction–acceleration effect.

• Experiments were performed in a Φ30 mm cold model and a Φ71 mm hot pilot plant of calcium looping.

• At low velocity, ΔPstatic (riser inventory) was found to be more than ΔPRiser in both CFBs.

• At higher velocity (3.6 m/s cold and 6 m/s hot), friction–acceleration became apparent.

Accurate information concerning riser inventory in a fluidized bed is required in some applications such as the calcium looping process, because it is related to the CO2 capture efficiency of the system. In a circulating fluidized bed (CFB), the riser inventory is normally calculated from the riser pressure drop; however, the friction and the acceleration phenomena may have a significant influence on the total riser pressure drop. Therefore, deviation may occur in the calculation from the actual mass. For this reason the magnitude of the friction and the acceleration pressure drop in the entire riser is studied in small-scale risers. Two series of studies were performed: the first one in a scaled cold model riser of the 10 kWth facility, and the second one in the 10 kWth fluidized bed riser under process conditions. The velocities were chosen to comply with the fluidization regimes suitable for the calcium looping process, namely, the turbulent and the fast. In cold-model experiments in a low-velocity turbulent fluidization regime, the actual weight (static pressure drop) of the particles is observed more than the weight calculated from a recorded pressure drop. This phenomenon is also repeated in pilot plant conditions. In the cold-model setup, the friction and acceleration pressure drop became apparent in the fast fluidization regime, and increased as the gas velocity rose. Within calcium looping conditions in the pilot plant operation, the static pressure drop was observed more than the recorded pressure drop. Therefore, as a conservative approach, the influence of friction pressure drop may be neglected while calculating the solid inventory of the riser. The concept of transit inventory is introduced as a fraction of total inventory, which lies in freefall zones of the CFB system. This fraction increases as gas velocity rises.