- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

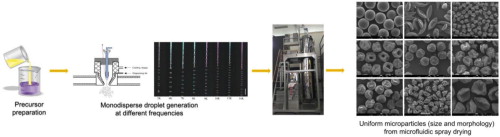

• Microfluidic spray drying can be used to produce uniform microparticles with tailored properties.

• Microparticle synthesis was exemplified with focus on microencapsulation and controlled release.

• Effects of formulation and drying conditions on functional particle properties were emphasised.

Spray drying is a typical method to produce particles in dry powder forms at industrial scale. Most spray-dried products often show a wide range of particle properties even within the same batch. At Monash University, we utilise a microfluidic spray drying approach to generate uniform microparticles with tightly controlled characteristics and sizes in a scalable, almost waste-free process. The technique is useful to correlate the effects of formulation and spray drying conditions on the properties of spray-dried particles, and can be used to test new formulations for targeted applications such as encapsulation and release of active ingredients. The synthesis route can be applied to other self-assembling systems, including mesoporous, crystalline, and hierarchically structured microparticles. As spray drying is commonly used in commercial scales, the understanding of how functional particles are formed in relation to formulations and process conditions could assist in developing a cost effective, energy and material-efficient route to produce powders with better properties and ease of handling for more advanced applications such as selective adsorption and bio-separation.