- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

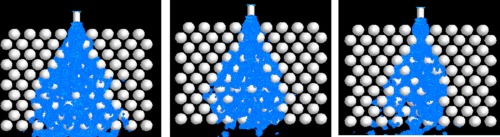

• Gas–liquid distribution in a packed bed was simulated using CFD and VOF model.

• Effects of influential parameters on radial liquid distributions and contact areas were studied.

• The number of wetted particles decreased with increasing gas velocity.

• The liquid radial distribution was greatly improved by increasing liquid flow rate.

In this work, computational fluid dynamics (CFD) simulations using the volume-of-fluid (VOF) model were employed to investigate the effects of liquid properties, liquid and gas flow rates, and wettability of particles on liquid maldistribution at the microscopic level in a fixed bed reactor. The simulation results show that the number of wetted particles decreases with increasing gas velocity, consequently leading to lower liquid–solid contact areas. The radial liquid distribution is greatly enhanced by increasing the liquid flow rate, whereas the time for the liquid to pass through the whole bed is decreased, as expected. Based on simulation results, it was found that the liquid–solid contact area can be increased by using liquids of high viscosities and more wettable particles. However, the flow-through time increases with increasing liquid viscosity. An increase in the gas density showed a minimal impact on the liquid flow-through time, and the liquid density does not impact the radial liquid distribution or the liquid flow time within a range of liquid densities typically encountered in the petrochemical industry.