- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

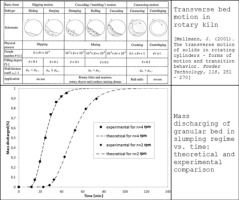

• Theoretical model for studying granule discharge from rotary kiln in slumping mode was developed.

• Theoretical data showed good agreement with experimental results of mean residence time.

• Axial segregation of particles indicated a dependence of residence time on particle diameters.

This study developed a theoretical approach to understanding how a set amount of a granular bed is discharged from a tilted rotary kiln (an empty cylinder) once its particle size distribution (PSD) is known and slumping motion occurs. The basis of the study is that the preparation of material for thermal treatment inside a rotary kiln (pyrolysis, gasification, and/or combustion) involves shredding to a desired particle size. Further mechanical stress results from the feeder screws moving material from storage toward the reactor. The most common PSDs found in uniform size reduction processes and mechanical stresses are Gaussian, log-normal, and Rosin–Rammler, of which the latter best fits the PSD in our study. Different particle diameters in the distribution result in an axial segregation when a slumping motion occurs, resulting in particles of different diameters leaving the kiln at different instants. After developing the model, the theoretical data showed good agreement when compared with experimental results obtained from downloading previously shredded carbonaceous material from a rotary kiln at 2 and 4 rpm rotational speeds. The mean residence times at steady state were determined for both rotational speeds and showed good agreement with data provided in the literature.