- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

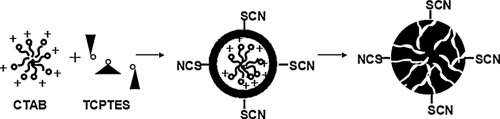

• A facile one-step sol–gel method was developed using cationic surfactants as template.

• Thiocyanato-functionalized porous silica nanospheres with size less than 23 nm were obtained.

• The porous structures and morphology of the samples could be controlled.

In this study, we present a facile method to prepare thiocyanato-functionalized porous silica nanospheres. Thiocyanato functionalized silica shells were coated on positively charged cetyltrimethylammonium bromide (CTAB) micelles via hydrolysis and condensation of (3-thiocyanatopropyl)triethoxysilane (TCPTES), the CTAB cores were removed subsequently to form thiocyanato-functionalized porous silica nanospheres. We demonstrate that the contents of the thiocyanato groups within the functionalized porous silica nanosphere frameworks gradually diminished as a function of hydrothermal treatment time at 100 °C until complete removal, confirmed by TGA and FTIR spectra. The data indicate that extended operation at relatively elevated temperatures may lead to the decomposition of the thiocyanato functional groups. In addition, at a lower CTAB concentration (0.0009 M), non-porous thiocyanato functionalized silica nanospheres were formed. However, increasing the CTAB concentration to 0.01 M resulted in porous nanospheres inferring that a CTAB concentration threshold is needed to form thiocyanato-functionalized porous silica nanospheres.