- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Automated microscopic imaging instrument was applied to measure polymorphic particle shape.

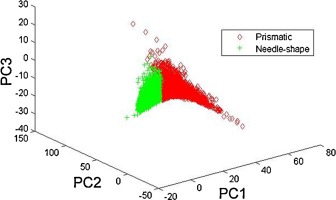

• Shape descriptors of physical meanings and based on Fourier transform and PCA were examined.

• A new method for calculating shape descriptors was proposed.

• The new shape descriptors proved to be able to effectively identify batch-to-batch variations.

It is known that size alone, which is often defined as the volume-equivalent diameter, is not sufficient to characterize many particulate products. The shape of crystalline products can be as important as size in many applications. Traditionally, particulate shape is often defined by several simple descriptors such as the maximum length and the aspect ratio. Although these descriptors are intuitive, they result in a loss of information about the original shape. This paper presents a method to use principal component analysis to derive simple latent shape descriptors from microscope images of particulate products made in batch processes, and the use of these descriptors to identify batch-to-batch variations. Data from batch runs of both a laboratory crystalliser and an industrial crystallisation reactor are analysed using the described approach. Qualitative and quantitative comparisons with the use of traditional shape descriptors that have physical meanings and Fourier shape descriptors are also made.