- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

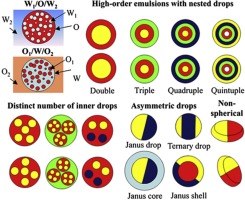

• Multiple emulsions of versatile shape and internal morphology can be produced.

• Encapsulation efficiency can reach 100% due to drop-by-drop manufacture approach.

• Non-planar and axisymmetric geometry of drop generators reduces wetting problems.

• Glass capillary devices can generate complex multiple emulsions in a single step.

• Fabricated drops are useful templates for multi-compartment particles and vesicles.

This review focuses on recent developments in the fabrication of multiple emulsions in micro-scale systems such as membranes, microchannel array, and microfluidic emulsification devices. Membrane and microchannel emulsification offer great potential to manufacture multiple emulsions with uniform drop sizes and high encapsulation efficiency of encapsulated active materials. Meanwhile, microfluidic devices enable an unprecedented level of control over the number, size, and type of internal droplets at each hierarchical level but suffer from low production scale. Microfluidic methods can be used to generate high-order multiple emulsions (triple, quadruple, and quintuple), non-spherical (discoidal and rod-like) drops, and asymmetric drops such as Janus and ternary drops with two or three distinct surface regions. Multiple emulsion droplets generated in microfabricated devices can be used as templates for vesicles like polymersomes, liposomes, and colloidosomes with multiple inner compartments for simultaneous encapsulation and release of incompatible active materials or reactants.