- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

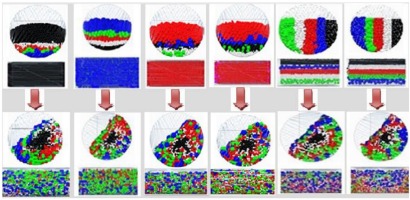

• Mixing of polydisperse particles in a rotary drum was evaluated using DEM method.

• Effects of drum rotational speed, particle size, and initial loading method were investigated.

• Good mixing could not be achieved for polydisperse particles as for monodisperse particles.

• Best mixing quality for polydisperse particles was achieved for the top–bottom initial loading.

• Addition of particles with sizes in between of the small and large particles reduced segregation.

Despite the wide applications of powder and solid mixing in industry, knowledge on the mixing of polydisperse solid particles in rotary drum blenders is lacking. This study investigates the mixing of monodisperse, bidisperse, tridisperse, and polydisperse solid particles in a rotary drum using the discrete element method. To validate the model developed in this study, experimental and simulation results were compared. The validated model was then employed to investigate the effects of the drum rotational speed, particle size, and initial loading method on the mixing quality. The degree of mixing of polydisperse particles was smaller than that for monodisperse particles owing to the segregation phenomenon. The mixing index increased from an initial value to a maximum and decreased slightly before reaching a plateau for bidisperse, tridisperse, and polydisperse particles as a direct result of the segregation of particles of different sizes. Final mixing indices were higher for polydisperse particles than for tridisperse and bidisperse particles. Additionally, segregation was weakened by introducing additional particles of intermediate size. The best mixing of bidisperse and tridisperse particles was achieved for top–bottom smaller-to-larger initial loading, while that of polydisperse systems was achieved using top–bottom smaller-to-larger and top–bottom larger-to-smaller initial loading methods.