- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

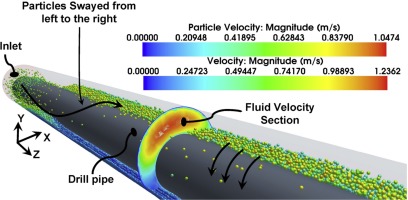

• Particle-fluid flow in a deviated well drilling was simulated using a CFD−DEM method.

• Irregularly shaped particles were constructed by multi-sphere method.

• Effect of particle shape on particle flow pattern and deposition were analyzed.

• Particle concentration and transport velocity increased with decreasing its sphericity.

We investigate the effect of particle shape on the transportation mechanism in well-drilling using a three-dimensional model that couples computational fluid dynamics (CFD) with the discrete element method (DEM). This numerical method allows us to incorporate the fluid–particle interactions (drag force, contact force, Saffman lift force, Magnus lift force, buoyancy force) using momentum exchange and the non-Newtonian behavior of the fluid. The interactions of particle−particle, particle−wall, and particle−drill pipe are taken into account with the Hertz–Mindlin model. We compare the transport of spheres with non-spherical particles (non-smooth sphere, disc, and cubic) constructed via the multi-sphere method for a range of fluid inlet velocities and drill pipe inclination angles. The simulations are carried out for laboratory-scale drilling configurations. Our results demonstrate good agreement with published experimental data. We evaluate the fluid–particle flow patterns, the particle velocities, and the particle concentration profiles. The results reveal that particle sphericity plays a major role in the fluid–solid interaction. The traditional assumption of an ideal spherical particle may cause inaccurate results.