- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Flowability of various dusts collected from the off-gas of secondary copper smelter was studied.

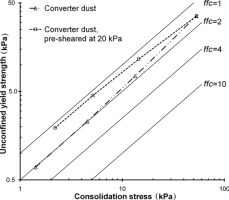

• Converter dust flowability dependence on consolidation stress was dissimilar to other dusts.

• The atypical converter dust behavior was explained by the presence of small agglomerates.

• Visualization of the flowability in a diagram was improved by using logarithmic scaled axes.

Stable flow of off-gas dust from dust collector hoppers and storage silos is important for smooth operation. Flow properties of the collected off-gas dust are critical to achieve suitable flow. Various dust samples collected from secondary copper smelter off-gases were studied. The median diameter of the fine-grained dusts varied from 0.8 to 1.4 μm and the flowability ranged from “cohesive” to “very cohesive”. The flowability of shaft and anode furnace dust improved slightly with increasing consolidation stress and their wall friction angles decreased, which is a typical behavior. In contrast, the flowability of converter dust decreased with increasing consolidation stress and its wall friction angles increased. Pre-shear treatment of converter dust worsened its flowability, increased the wall friction angle, and improved the flowability with increasing consolidation stress. This is believed to occur because pre-shear treatment fragments small agglomerates in the dust that improve flowability. The presence of such agglomerates was confirmed by sieving tests. A diagrammatic representation of the flowability showing that the unconfined yield strength is dependent on consolidation stress can be improved by using logarithmically scaled axes.