- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

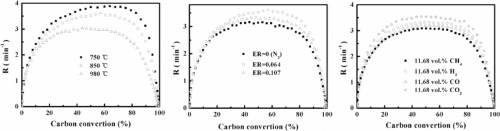

• Continuous coal pyrolysis was studied in complex atmospheres at high temperatures.

• At ER of 0.064 char had the highest specific surface area and oxidation reactivity.

• In O2-free atmosphere the presence of CH4 and CO decreased char specific surface area.

• Presence of H2 and CH4 condensed char crystallite structure to lower oxidation activity.

The physiochemical properties of chars produced by coal pyrolysis in a laboratory-scale fluidized bed reactor with a continuous coal feed and char discharge at temperatures of 750 to 980 °C under N2-based atmospheres containing O2, H2, CO, CH4, and CO2 were studied. The specific surface area of the char was found to decrease with increasing pyrolysis temperature. The interlayer spacing of the char also decreased, while the average stacking height and carbon crystal size increased at higher temperatures, suggesting that the char generated at high temperatures had a highly ordered structure. The char obtained using an ER value of 0.064 exhibited the highest specific surface area and oxidation reactivity. Relatively high O2 concentrations degraded the pore structure of the char, decreasing the surface area. The char produced in an atmosphere incorporating H2 showed a more condensed crystalline structure and consequently had lower oxidation reactivity.