- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

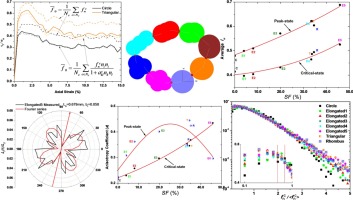

• SF is a better shape descriptor in evaluating granular mechanical behaviour.

• Strength indexes and anisotropic coefficients increased linearly with SF at steady state.

• Average normal contact forces and contact vectors could influence stress–force–fabric accuracy.

• Frictional mobilization and contact force chain could be used to explain macro physical property.

Particle shape plays an important role in both the micro and macro scales responses of a granular assembly. This paper presents a systematic way to interpret the shape effects of granular material during quasi-static shearing. A more suitable shape descriptor is suggested for the quantitative analysis of the macroscale strength indexes and contact parameters for non-convex grains, with special consideration given to the peak state and critical state. Through a series of numerical simulations and related post-processing analysis, particle shape is found to directly influence the strain localisation patterns, microscale fabric distributions, microscale mobilisation indexes, and probability distribution of the normalised contact normal force. Additionally, the accuracy of the stress–force–fabric relationship can be influenced by the average normal force and the distribution of contact vectors. Moreover, particle shape plays a more important role than do the confining pressures in determining the friction angle. Strong force chains and the dilation effect are also found to be strongly influenced by the high confining pressure.