- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

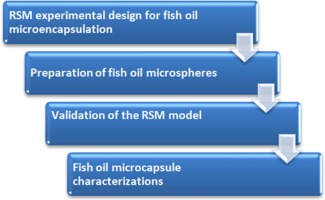

• Fish oil microcapsules were prepared using alginate and chitosan as the wall materials.

• Optimal microencapsulation conditions were obtained via response surface methodology.

• Microcapsules prepared by emulsification method showed higher encapsulation efficiency.

• Chitosan–alginate complexes have the potential as a nutrient delivery system.

Fish oil microcapsules were prepared using two natural polysaccharides, alginate and chitosan, as the wall materials. A response surface methodology (RSM) was used to optimize the conditions for fish oil encapsulation efficiency (FOEE). The FOEE was investigated with respect to three key-variables in the RSM: ratio of inner oil phase to aqueous phase (X1, w/w); concentration of the aqueous phase (X2, wt%); and ratio of the aqueous phase to outer oil phase (X3, v/v). The optimal formulation obtained from the RSM model, i.e., 2.7:1 (X1), 1.6 wt% (X2), and 11.5:1 (X3), gave a FOEE of 28%. The model was validated and the fish oil microcapsules prepared under the optimized conditions were characterized in terms of particle size, polydispersity index (PDI), zeta potential, surface morphology, and in vitro release. The average droplet size, PDI, and zeta potential were 915 nm, 0.038, and +5.2 mV, respectively. The fish oil microcapsules were highly uniform microspheres, and had an accumulative release rate of 77.7% in 270 min in a gastrointestinal model, indicating their potential as an alternative carrier for the controlled release of fish oil. In conclusion, formulating optimal microencapsulation conditions by the RSM can be applied to the microencapsulation of various oil-soluble nutrients for food applications.