- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

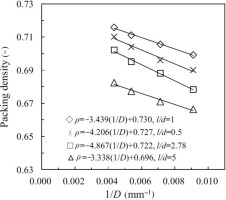

• Packing densification of cylinders under 3D mechanical vibration was experimentally studied.

• The influences of vibration conditions on the packing density were analyzed.

• The maximum random packing density for equiaxed cylinders obtained experimentally was about 0.73.

Systematic physical experiments examining the packing densification of mono-sized cylindrical particles subject to 3D mechanical vibration were carried out. The influence of vibration conditions such as vibration time, frequency, amplitude, vibration strength, container size, and the aspect ratio and sphericity of the particle on the packing density were analyzed and discussed. For each initial packing density with a certain aspect ratio, operating parameters were optimized to achieve much denser packing. The results indicate that the packing density initially increases with vibration time and then remains constant. The effects of vibration frequency and amplitude on the packing densification have similar trends, i.e. the packing density first increases with the vibration frequency or amplitude to a high value and then decreases; too large or small frequency or amplitude does not enhance densification. Increasing the container size can reduce container wall effects and help achieve a high packing density. Varying the particle aspect ratio and sphericity can lead to different dense random packing structures. Overall, based on results of the examined systems, the highest random packing density obtained in an infinite sized container can reach 0.73, which agrees well with corresponding numerical and analytical results in the literature.