- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

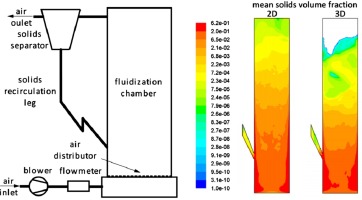

• Experimental and numerical studies of pseudo-2D CFBs were performed.

• Measured pressure and solid volume fractions were compared with simulation results.

• Sensitivity of simulation results to mesh density was studied.

• Effects of particle size distribution and granular temperature formulation were examined.

• 3D effects were shown to be important in modeling of the pseudo-2D facility.

We present experimental investigations and numerical simulations of a pseudo-2D riser. Experiments were performed for various airflow rates, particle types/diameters, and particle size distributions. Pressure distributions along the wall of the riser were measured. Additional measurements from a smaller pseudo-2D riser (Kallio et al., 2009; Shah et al., 2012) were used to analyze horizontal solids volume fraction profiles. The experimental data were compared with simulation results carried out using an Euler–Euler approach. A mesh sensitivity study was conducted for numerical simulations and effects associated with simplifying real 3D geometry to a 2D model were examined. In addition, the effect of using an algebraic equation to represent the granular temperature versus a full partial differential equation also was examined for numerical simulations. Results showed small but significant near-wall sensitivity of the flow variables to mesh size. Substantial differences in mean pressure, solids distribution, and solid velocities were obtained, when 2D and 3D simulation results were compared. Finally, applying the simplified granular temperature equation for turbulent fluidization and for dilute-phase transport can lead to incorrect predictions in models.