- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• The discharge of a granular material from a hopper was modelled.

• Residence time distribution (RTD) was calculated for flat and heaped powder layers.

• Increasing layer angle decreased the spread of the RTD.

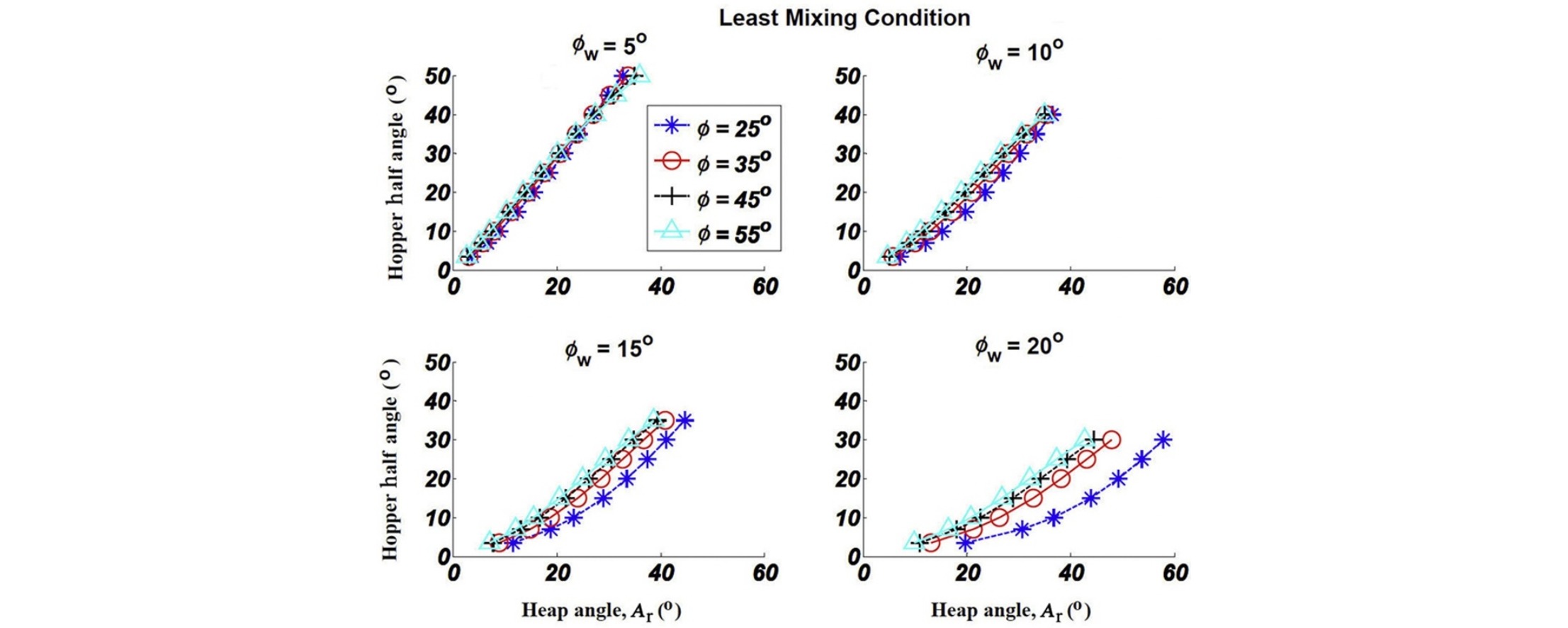

• The critical angle to minimise the spread of the RTD was calculated.

A wedge-shaped planar mass-flow hopper system was modelled using stress-field theory as found in the literature. The authors present governing equations for stress and velocity fields under a radial-flow assumption in a converging hopper. The velocity in the silo above the hopper is modelled as plug flow. Two set-ups are modelled, one where powder layers in the hopper are assumed to be flat, and the second in which the layers are heaped at some characteristic angle. The ejection times and residence-time distributions are calculated and presented for a range of heap angles. For realistic heap angles, the spread of the residence-time distribution decreases with increasing heap angle; in one case, the spread is halved to a well-defined limit. At this limit (the critical heap angle) the geometry of the hopper can be optimised to minimise the spread of the residence-time distribution, and hence to minimise predicted mixing in the system. We present examples of curves for a variety of parameters that minimise the predicted mixing in the hopper–silo system.