- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

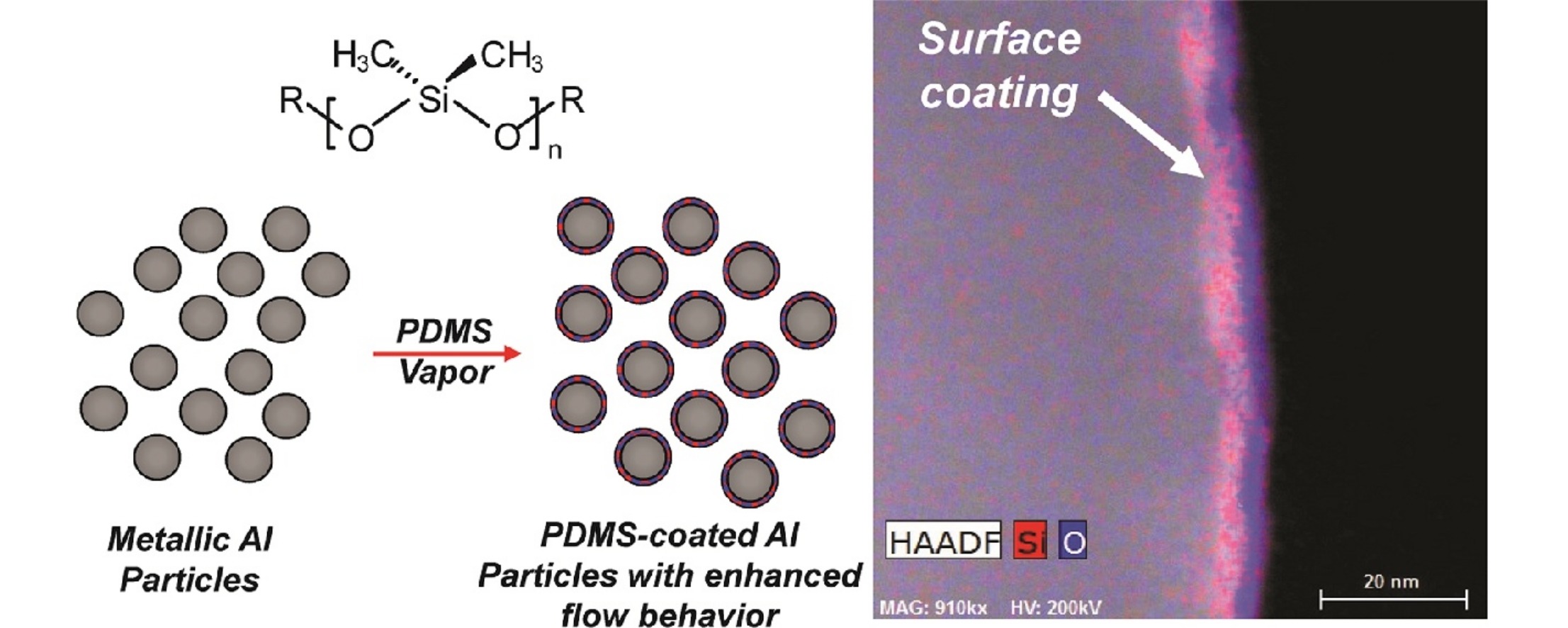

• Polydimethylsiloxane was successfully deposited on metallic aluminum particles.

• Improved flow properties were observed through reduced cohesion.

• Fluidization behavior was improved as shown through aeration testing.

Aluminum particles were exposed to gaseous polydimethylsiloxane (PDMS) to produce a hydrophobic surface coating for enhanced flow and fluidity. Surface retention of the intact PDMS was confirmed through infrared and X-ray photoelectron spectroscopy. Transmission electron microscopy was used to image cross-sections of the treated particles and energy dispersive spectroscopy element maps demonstrated the presence of a surface layer consisting of silicon and oxygen. Density measurements provided evidence for improvements in the Hausner ratio and Carr index of the PDMS-treated aluminum, indicating a reduction in inter-particulate cohesion through increased bulk density. Stability, compressibility, shear, aeration, and permeability of the particles were assessed by powder rheometer. The compressibility was reduced by approximately 32% following surface treatment, revealing a reduction in void space, while Mohr’s circle analysis and shear testing determined that the extrapolated cohesion value was reduced by approximately 53% and the flow factor at 6 kPa was doubled. Aeration testing showed that the air velocity required to obtain a fluidized bed was on the order of 0.35 mm/s for the treated powder, whereas the raw powder could not be uniformly fluidized. PDMS may be a viable option for the large-scale treatment of aluminum powder for flow applications.