- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

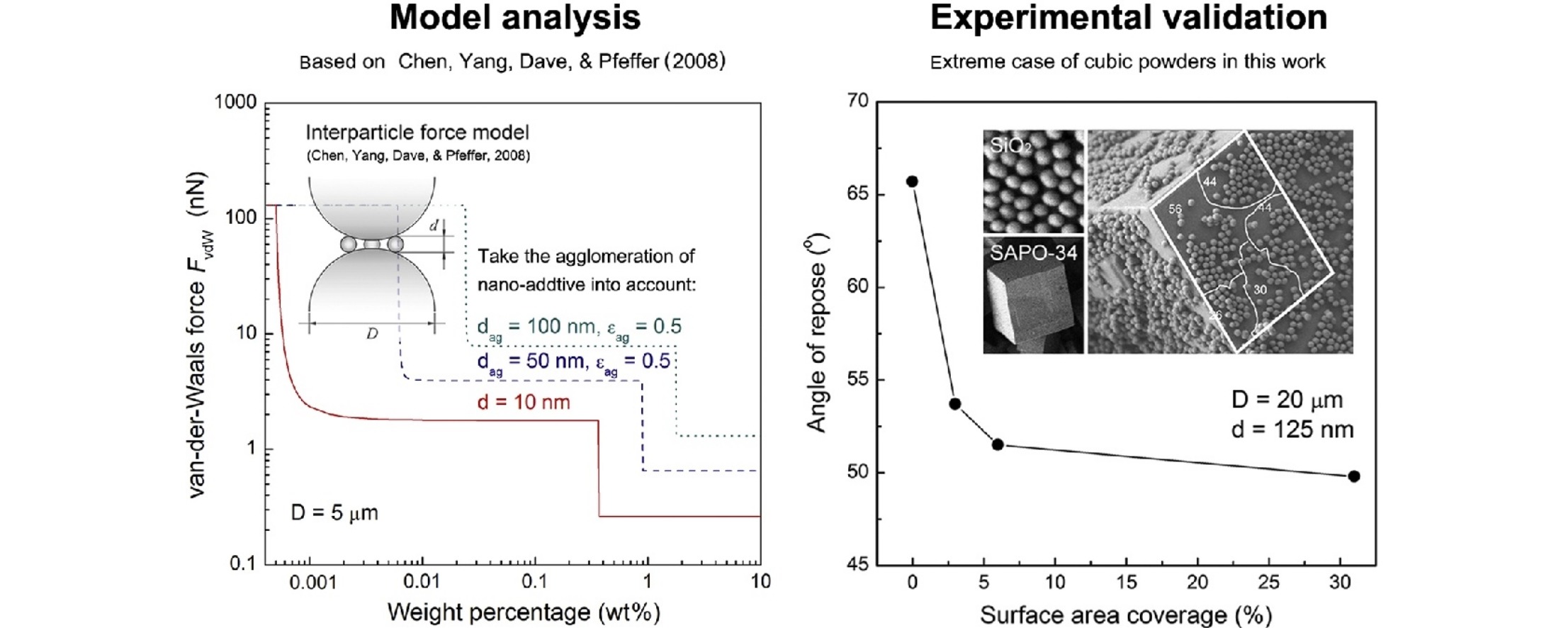

• Mechanism of nano-additives in reducing powder cohesiveness was theoretically analyzed.

• Properly coating with nanoparticles could improve flowability of irregular shape cohesive powders.

• An empirical criterion was proposed to predict coated powder flowability in terms of Co number.

Fluidization of fine cohesive powders is seriously restricted by the strong interparticle cohesion. The rational combination of nanoparticles with fine cohesive powders is expected to obtain composite particles with improved flowability. In this work, we firstly reviewed the sandwich and three-point contact models regarding the fundamental principles of nano-additives in reducing cohesiveness. Based on these previous models, the effects of the size of nanoparticles, their agglomeration and coverage on the surface of cohesive powders in reducing interparticle forces were theoretically analyzed. To validate the theory effectiveness for the irregularly shaped cohesive powders, an extreme case of cubic powders coated with silica nanoparticles was fabricated, and the flowability of the composite particles was determined experimentally. Ultimately, based on force balance of a single particle, a semi-theoretical criterion for predicting the fluidization behavior of coated powders was developed to guide the practical applications of improving the flowability of cohesive powders through structural design and modulation.