- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

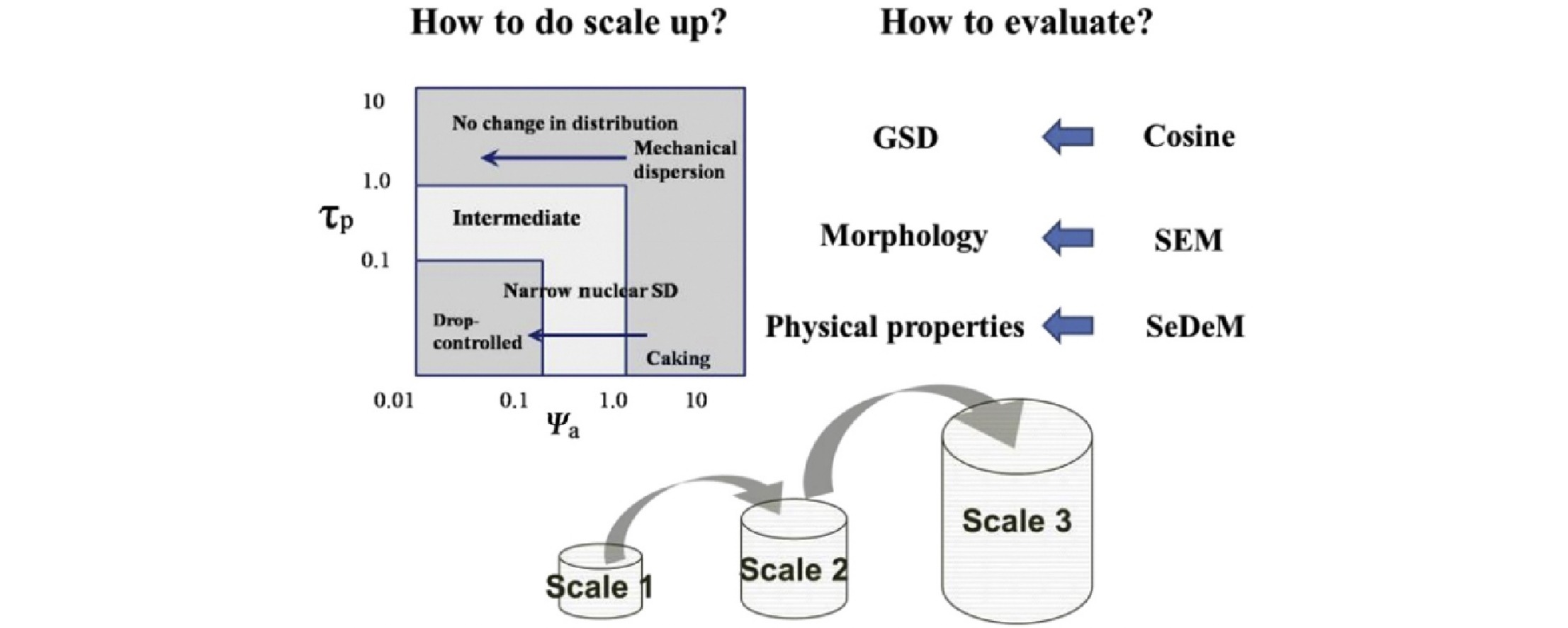

• The scale up of high shear wet granulation (HSWG) process was conducted by a regime map approach.

• Granule properties were evaluated to examine the similarity of granules of different scales.

• SeDeM method was applied to quantify the suitability of the granules for direct compression.

• The application of nucleation regime map to scale up HSWG process was feasible.

Scale-up of the high shear wet granulation (HSWG) process is considered a challenge because HSWG is complex and influenced by numerous factors, including equipment, formulation, and process variables. For a system of microcrystalline cellulose and water, HSWG experiments at three scales (1, 2, and 4 L working vessel) were conducted with a granulator. Scale-up was implemented on the basis of a nucleation regime map approach. To keep dimensionless spray flux and drop penetration time constant, water addition time at three processing scales were 300, 442, and 700 s, respectively. The other process parameters were kept unchanged. Granule size distributions were plotted and compared, and scanning electron microscopy was used to analyze granule surface morphology. Physical characterization was undertaken using a modified SeDeM method. At nearly all scales, granule yield was greater than 85% and all the cosine values were larger than 0.89. At the same experiment points, granules at all scales had similar surface morphology and similar physical characteristics. The results demonstrate that a rational scaling-up of the HSWG process is feasible using a regime map approach.