- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

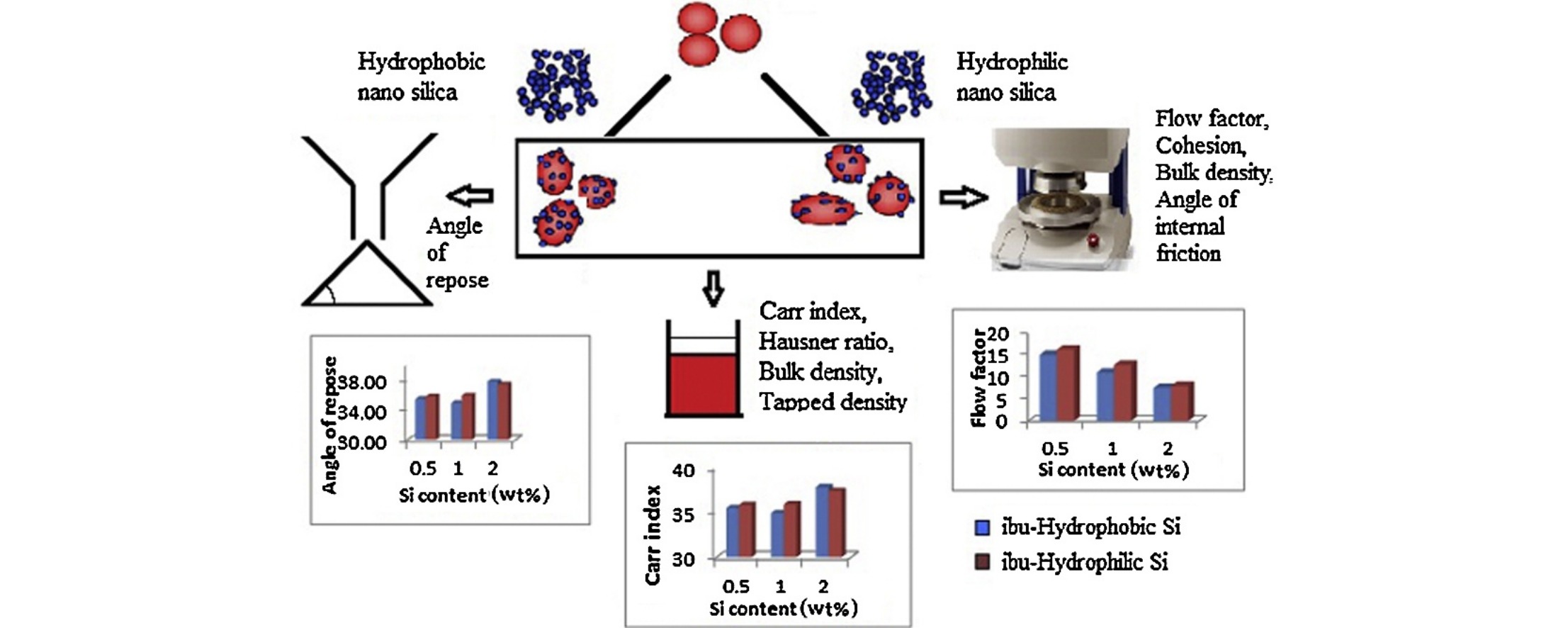

• Glidant effect of nanosilica varied with their nature of hydrophobicity or hydrophilicity and the amount used.

• No single established method was sufficient to demonstrate flow behavior of the bulk powder mass.

• Change of bulk density with consolidation pressure was proposed as a powder flow characterization.

The methods used for flow characterization of a powder mass include the angle of repose (AOR), Carr index (CI), and powder flow tester (PFT). The use of nanosilica as a flow modifier (glidant) is very common in industry. This study aims to compare the glidant effect of hydrophobic and hydrophilic silica on a poorly flowable active pharmaceutical ingredient (ibuprofen) by different flow characterization techniques. Different percentages (0.5, 1.0, and 2.0 wt%) of both types of mixed silica–ibuprofen powders were evaluated by the AOR, CI, bulk density, and PFT. The flow factor, effective angle of friction, and cohesion were determined to explain the bulk powder properties. The results show that different types of silica show different levels of flow property improvement, but the techniques do not equally discriminate the differences. Hydrophobic silica results in better improvement of the flow property than hydrophilic silica, probably because of its better surface coverage of silica on the host particles. Change of the bulk density with applied pressure was significant for the different powders. This study demonstrates that combining several characterization methods provides a better understanding of bulk powder flow properties with respect to powder–process relationships than a single flow indicator.