- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

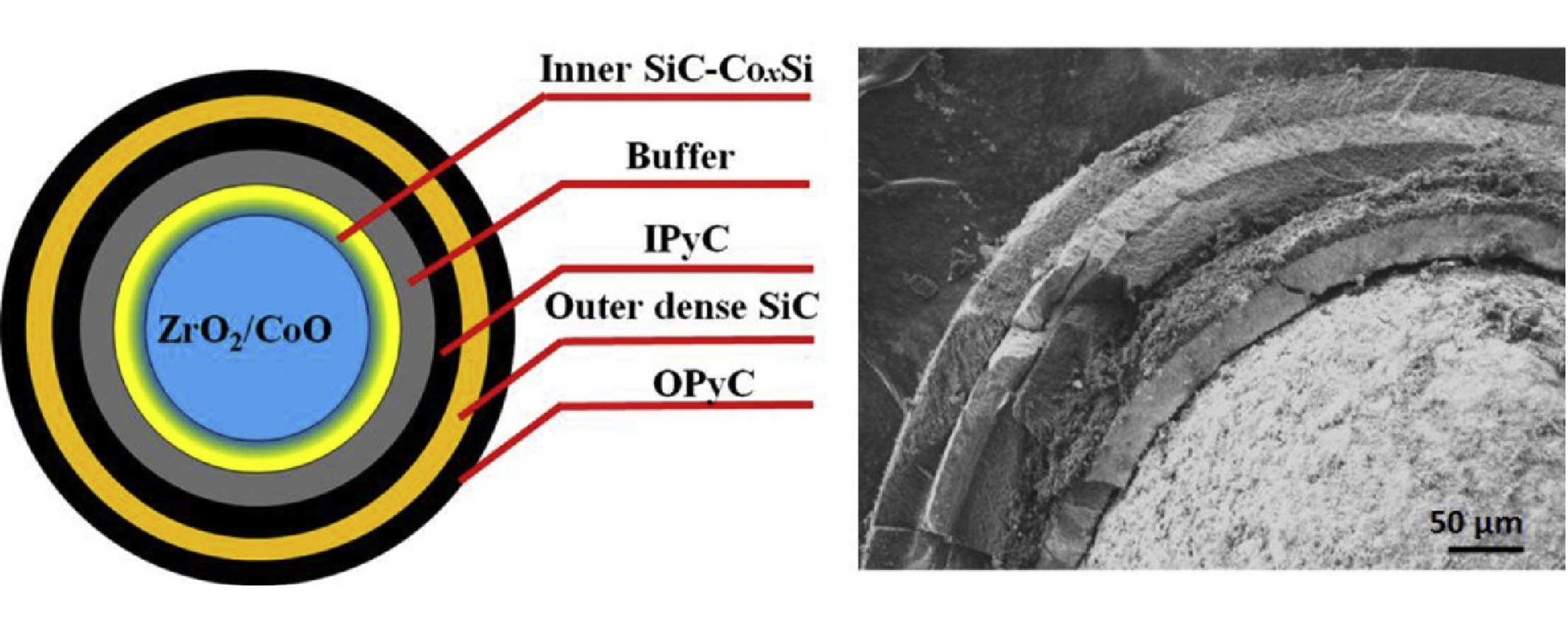

• A novel coated particle structure design used in nuclear power plant was proposed.

• High-density SiC layer was coated on particle containing cobalt element.

• An inner high-density SiC-CoxSi layer was obtained by a modified FB-CVD method.

• The new particle design could prevent the formation and diffusion of cobalt in coating process.

• The coated particle could maintain structure integrity in extreme high temperature.

Particle coating is an important method that can be used to expand particle-technology applications. Coated-particle design and preparation for nuclear fuel-element trajectory tracing were focused on in this paper. Particles that contain elemental cobalt were selected because of the characteristic gamma ray spectra of 60Co. A novel particle-structure design was proposed by coating particles that contain elemental cobalt with a high-density silicon-carbide (SiC) layer. During the coating process with the high-density SiC layer, cobalt metal was formed and diffused towards the coating, so an inner SiC–CoxSi layer was designed and obtained by fluidized-bed chemical vapor deposition coupled with in-situ chemical reaction. The coating layers were studied by X-ray diffractometry, scanning electron microscopy, and energy dispersive X-ray spectroscopy techniques. The chemical composition was also determined by inductively coupled plasma optical emission spectrometry. The novel particle design can reduce the formation of metallic cobalt and prevent cobalt diffusion in the coating process, which can maintain safety in a nuclear reactor for an extended period. The experimental results also validated that coated particles maintain their structural integrity at extremely high temperatures (∼1950 °C), which meets the requirements of next-generation nuclear reactors.