- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

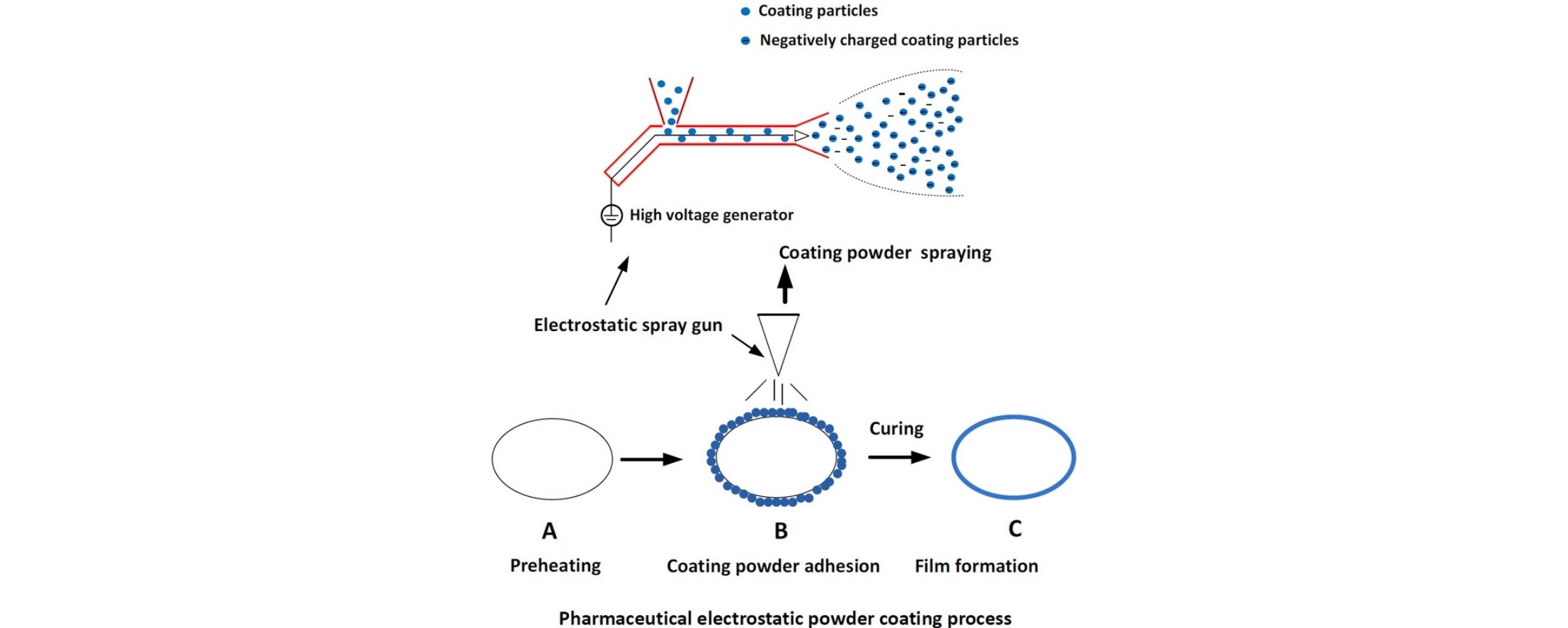

• A brief introduction of electrostatic dry powder coatings was given.

• Principles, apparatus, and formulations of the "ExsicCoat" technology were summarized.

• Film formation could be influenced by the curing temperature, time, and particle size.

• Future work includes moisture sensitive drugs, coating materials with high Tg.

Derived from dry powder coating of metals, electrostatic powder coating for pharmaceuticals is a technology for coating drug solid dosage forms. In this technology, coating powders, containing coating polymers, pigments, and other excipients, are directly sprayed onto the surface of the solid dosage forms through an electrostatic gun without using any organic solvent or water. The deposited coating powders are further cured to form a coating film. Electrostatic powder coating technology has many advantages compared to other pharmaceutical coating methods. It can eliminate the limitations caused by the organic solvent in solvent coating such as environmental issues and health problems. And electrostatic powder coating technology also surpasses aqueous coating due to its shorter processing time and less energy consumption, leading to a lower overall cost. Furthermore, the utilization of electrical attraction can promote the movement of coating powders towards the substrate, leading to an enhanced coating powder adhesion and coating efficiency, which make it more promising compared to other dry coating technologies. The objective of this review is to summarize the coating principles, apparatus, and formulations of different electrostatic powder coating technologies, giving their advantages and limitations and also analyzing the future application in the industry for each technology.