- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• An L-valve was modeled using actual solid frictional pressure.

• Critical solid frictional pressure underestimated the frictional forces in dense particle flow.

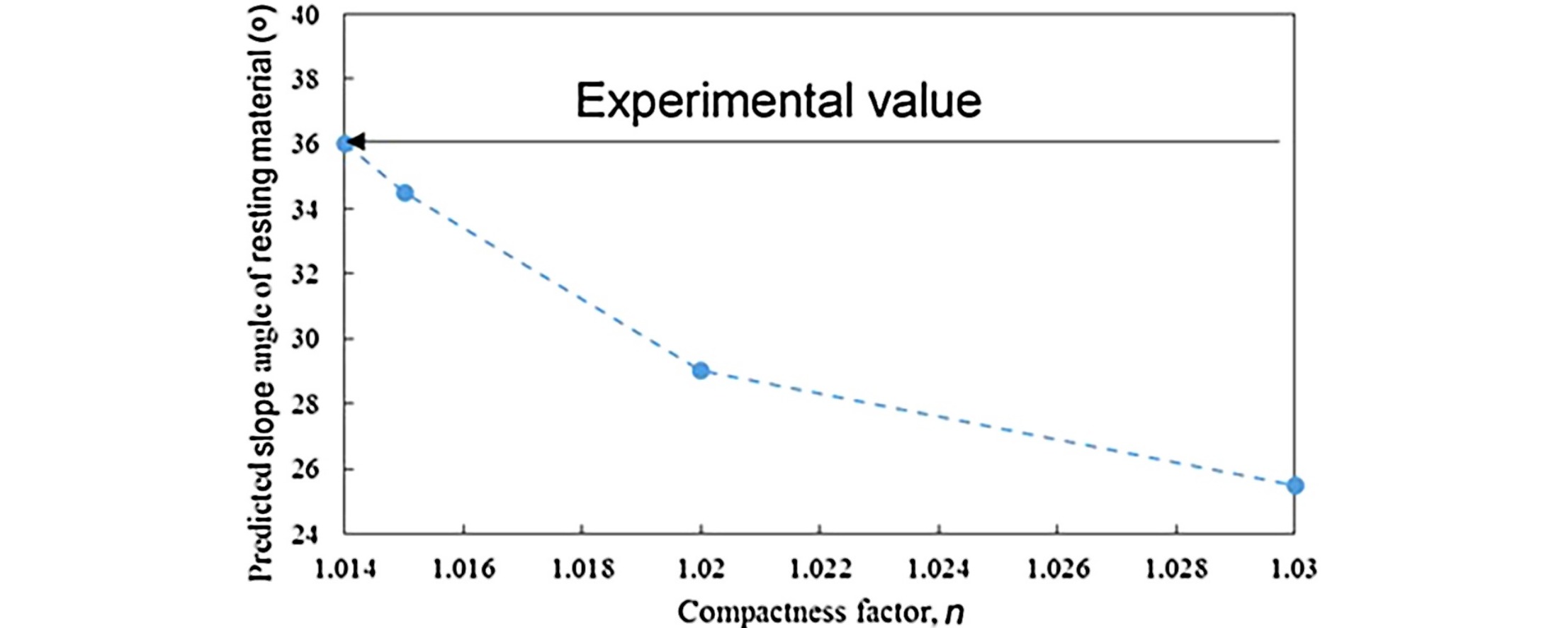

• A new approach was devised capable of predicting angle of repose more accurately.

• Effects of different parameters on the solid flow in the frictional regime were studied.

Dense gas–solid flows show significantly higher stresses compared with dilute flows, mainly attributable to particle–particle friction in dense particle flows. Several models developed have considered particle–particle friction; however, they generally underestimate its effect in dense regions of the gas–solid system, leading to unrealistic predictions in their flow patterns. Recently, several attempts have been made to formulate such flows and the impact of particle–particle friction on predicting flow patterns based on modified frictional viscosity models by including effects of bulk density changes on frictional pressure of the solid phase. The solid–wall boundary is also expected to have considerable effect on friction because particulate phases generally slip over the solid surface that directly affects particle–particle frictional forces. Polydispersity of the solid phase also leads to higher friction between particles as more particles have sustained contact in polydispersed systems. Their effects were investigated by performing CFD simulations of particle settlement to calculate the slope angle of resting material of non-cohesive particles as they settle on a solid surface. This slope angle is directly affected by frictional forces and may be a reasonably good measure of frictional forces between particles. The calculated slope angle, as a measure of frictional forces inside the system are compared with experimental values of this slope angle as well as simulation results from the literature.