- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

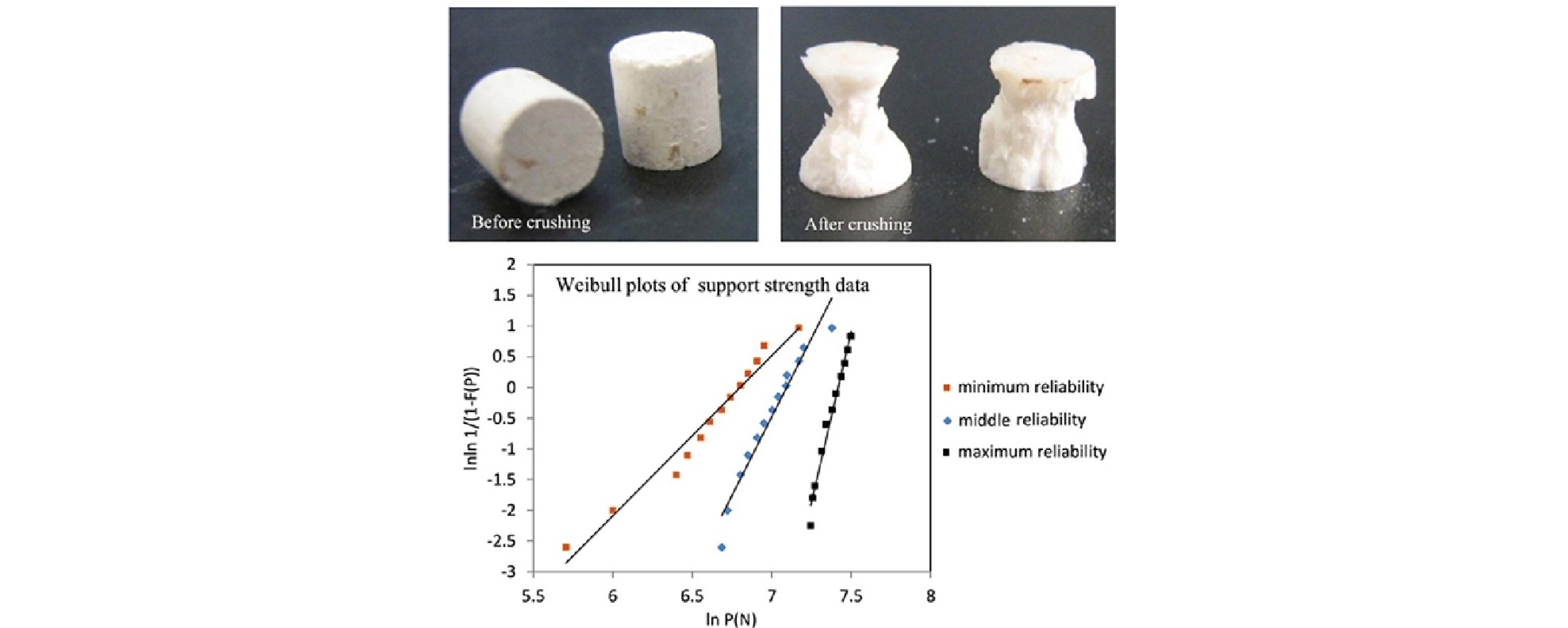

• Binder concentration and drying method significantly affected the support strength.

• The most reliable catalyst was obtained using support with the lowest strength.

• Weibull modulus could be used as a reliability control index for industry catalyst production.

A fundamental step in the production of an industrial catalyst is its crushing strength assessment. Limited literature exists in which the strength reliability of supported catalysts is investigated from production to their application in a reactor. In this work, cylindrical supports were prepared by pelletizing high porosity γ-alumina powder, and Cu–Zn/γ-Al2O3 catalysts were prepared by impregnation of the pelletized γ-alumina supports with an aqueous solution of copper and zinc nitrates. The support-forming variables, such as binder concentration, compaction pressure, calcination temperature, and drying procedure were investigated. The Weibull method was used to analyze the crushing strength data of the supports, and the fresh and used catalysts before and after the low-temperature water gas shift reaction. Support formation at a 50 wt% binder concentration, 1148 MPa compaction pressure, 500 °C calcination temperature, and rapid drying (100 °C, 8 h) led to the maximum support mechanical reliability. The most reliable catalyst with respect to simultaneous appropriate catalytic performance and mechanical strength was prepared from a support with the lowest mean crushing strength (26.25 MPa). This work illustrates the importance of the Weibull modulus as a useful mechanical reliability index in manufacturing a supported solid catalyst.