- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

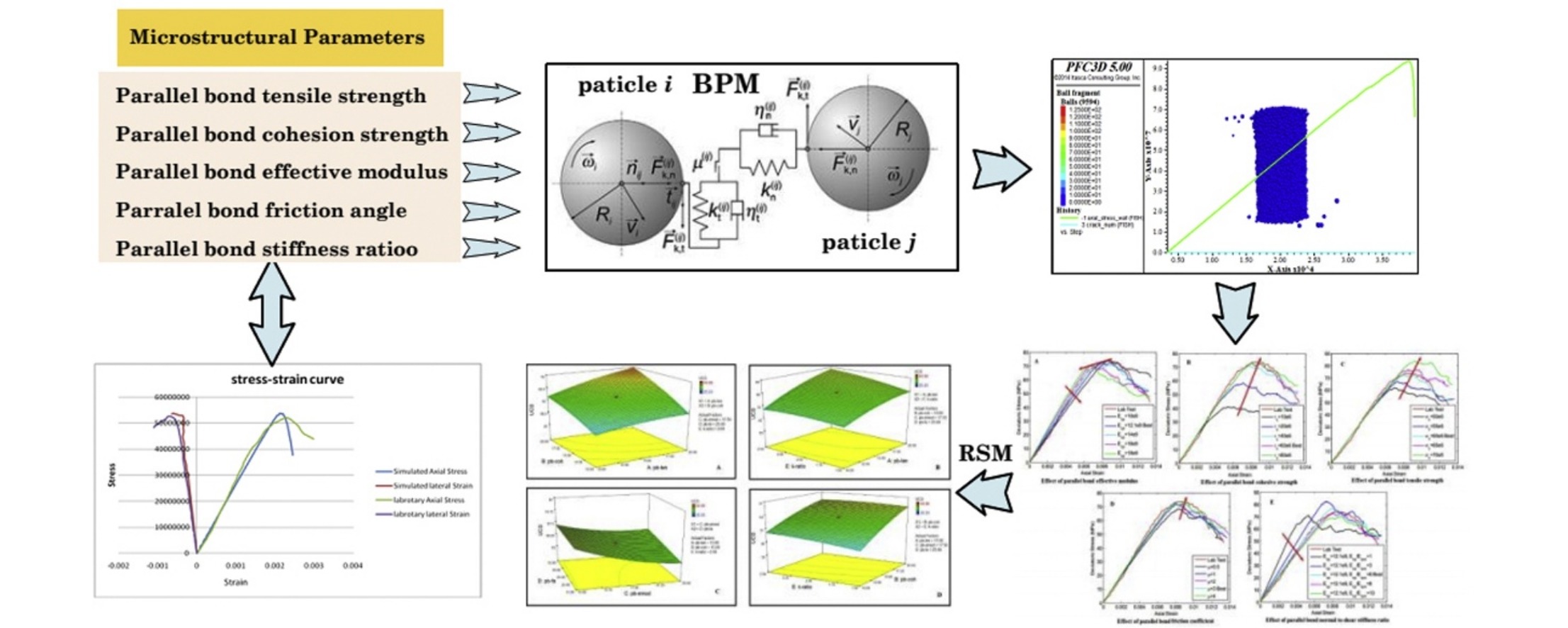

• RSM and CCD were used to analyze the effects of microparameters in a BPM calibration process.

• Elasticity modulus was highly correlated to the parallel bond effective modulus.

• Both parallel bond tensile and cohesion strengths had considerable effects on UCS.

The bonded-particle model (BPM) is commonly used in numerical analysis of the mechanical behavior of rock samples. Constructing a BPM model requires specification of a number of microstructural parameters, including the parallel-bond tensile strength, parallel-bond cohesion strength, parallel-bond effective modulus, parallel-bond friction angle, and parallel-bond stiffness ratio. These parameters cannot be easily measured in the laboratory or directly related to either measurable or physical material parameters. Hence, a calibration process is required to choose the values to be used in simulations of physical systems. In this study, response surface methodology along with the central composite design approach is used to calibrate BPMs. The sensitivities of the microparameters related to the uniaxial compressive strength (UCS) and elasticity modulus (i.e., the macroscopic responses of the models) are thoroughly scrutinized. Numerical simulations are performed to carefully assess the performance of the model. It is found that the elasticity modulus is highly correlated with the parallel-bond effective modulus. In addition, the parallel-bond tensile and cohesion strengths are the two most significant microparameters with a considerable effect on the UCS. The predicted values determined by the proposed approach are in good agreement with the observed values, which verifies the applicability of the proposed method.