- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

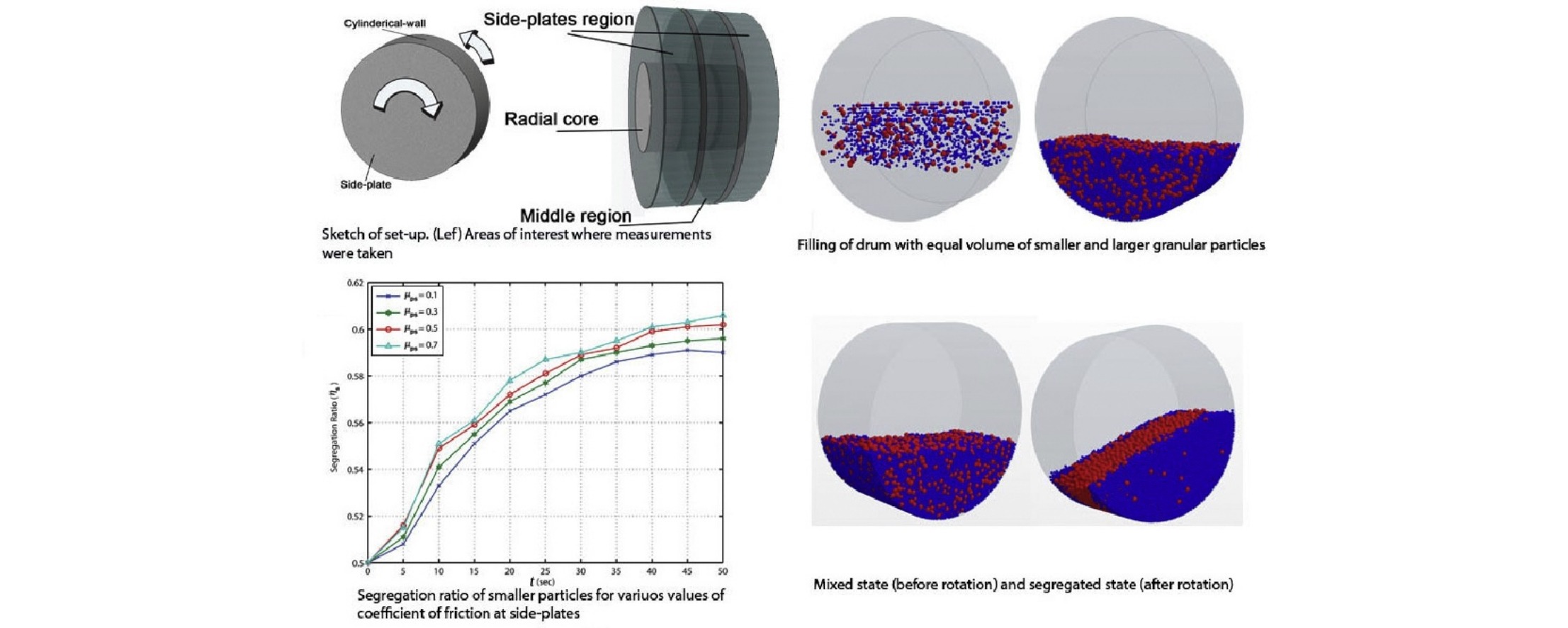

• Shear-drive size segregation of binary granular particles in drum was simulated.

• Anti-spinning of side plates caused migration of smaller particles toward side-plates.

• Coefficient of friction on the side-plates caused more migration toward side-plates.

• Radial segregation was diminished in the system configuration.

Segregation and mixing of granular materials are complex processes and are not fully understood. Motivated by industrial need, we performed a simulation using the discrete element method to study size segregation of a binary mixture of granular particles in a horizontal rotating drum. Particles of two different sizes were poured into the drum until it was 50% full. Shear-driven segregation was induced by rotating the side-plates of the drum in the opposite direction to that of the cylindrical wall. We found that radial segregation diminished in these systems but did not completely vanish. In an ordinary rotating drum, a radial core of smaller particles is formed in the center of the drum, surrounded by larger revolving particles. In our system, however, the smaller particles were found to migrate toward the side-plates. The shear from anti-spinning side-plates reduces the voidage and increases the bulk density. As such, smaller particles in the mixer tend to move to denser regions. We varied the shear by changing the coefficient of friction on the side-plates to study the influence of shear rate on this migration. We also compared the extent of radial segregation with stationary side-plates and with side-plates moving in different angular directions.