- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

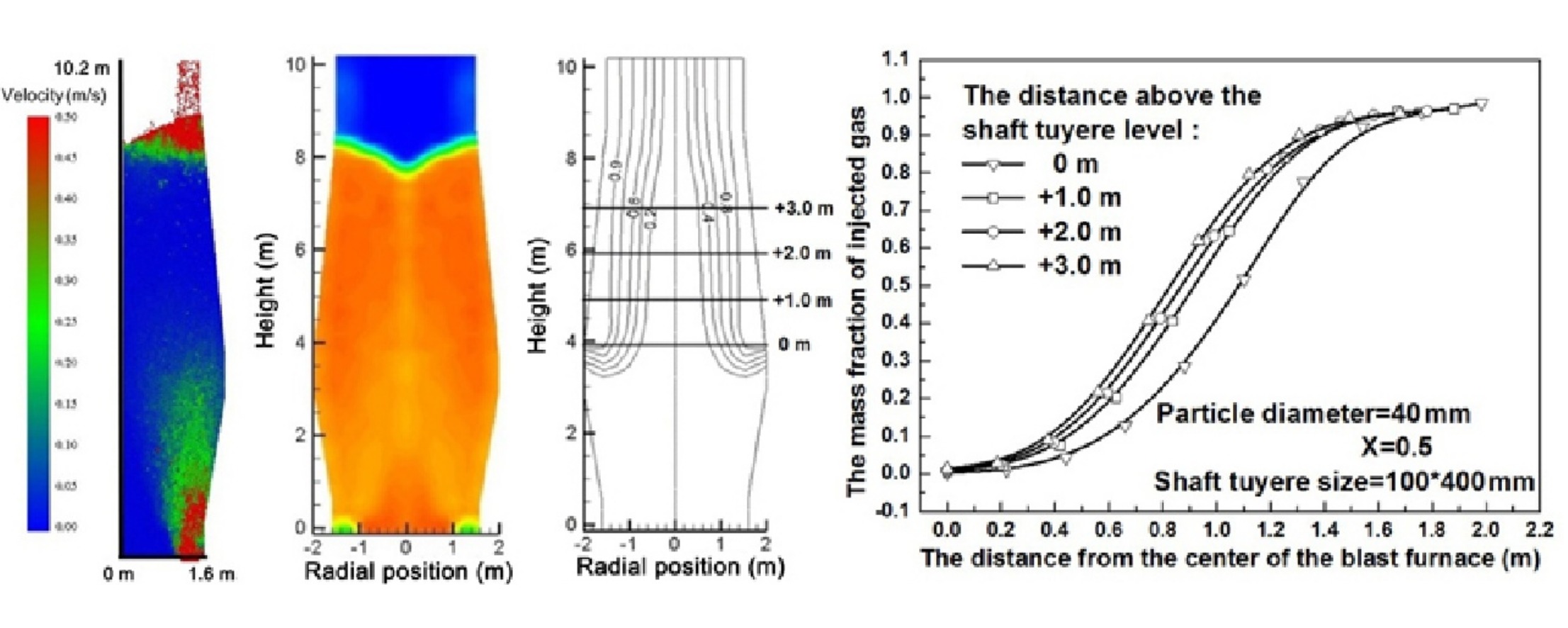

• Gas–solid flow characteristics in oxygen blast furnace was studied by DEM–CFD coupled model.

• DEM–CFD coupled model was established and applied to study particle distribution characteristics.

• Shaft-injected gas penetration distance in the furnace decreased as the particle diameter decreased.

• In essence, improving gas pressure from shaft tuyere was helpful for injected gas penetrating.

• The model reliability was verified by previous experimental results.

Ironmaking using an oxygen blast furnace is an attractive approach for reducing energy consumption in the iron and steel industry. This paper presents a numerical study of gas–solid flow in an oxygen blast furnace by coupling the discrete element method with computational fluid dynamics. The model reliability was verified by previous experimental results. The influences of particle diameter, shaft tuyere size, and specific ratio (X) of shaft-injected gas (SIG) flowrate to total gas flowrate on the SIG penetration behavior and pressure field in the furnace were investigated. The results showed that gas penetration capacity in the furnace gradually decreased as the particle diameter decreased from 100 to 40 mm. Decreasing particle diameter and increasing shaft tuyere size both slightly increased the SIG concentration near the furnace wall but decreased it at the furnace center. The value of X has a significant impact on the SIG distribution. According to the pressure fields obtained under different conditions, the key factor affecting SIG penetration depth is the pressure difference between the upper and lower levels of the shaft tuyere. If the pressure difference is small, the SIG can easily penetrate to the furnace center.