- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

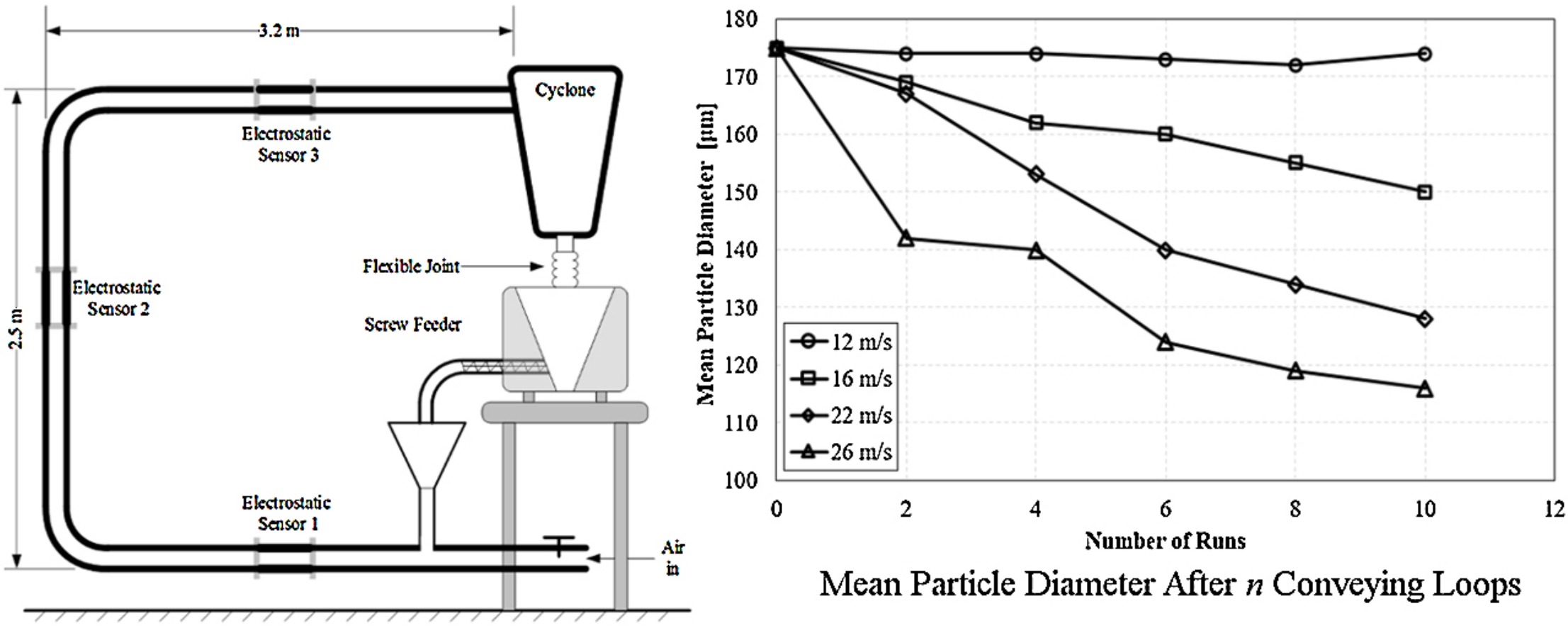

• Particle degradation was proportional to the air inlet velocity in dilute pneumatic conveying.

• Electrostatic sensor signal reduction was proportional to the degree of particle degradation.

• Particle degradation induced attenuation of flow velocity fluctuations based on CFD–DEM modelling.

Vigorous particle collisions and mechanical processes occurring during high-velocity pneumatic conveying often lead to particle degradation. The resulting particle size reduction and particle number increase will impact on the flow characteristics, and subsequently affect the electrostatic type of flow measurements. This study investigates this phenomenon using both experimental and numerical methods. Particle degradation was induced experimentally by recursively conveying the fillite material within a pneumatic pipeline. The associated particle size reduction was monitored. Three electrostatic sensors were embedded along the pipeline to monitor the flow. The results indicated a decreasing trend in the electrostatic sensor outputs with decreasing particle size, which suggested the attenuation of the flow velocity fluctuation. This trend was more apparent at higher conveying velocities, which suggested that more severe particle degradation occurred under these conditions. Coupled computational fluid dynamics and discrete element methods (CFD–DEM) analysis was used to qualitatively validate these experimental results. The numerical results suggested that smaller particles exhibited lower flow velocity fluctuations, which was consistent with the observed experimental results. These findings provide important information for the accurate application of electrostatic measurement devices in pneumatic conveyors.