- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

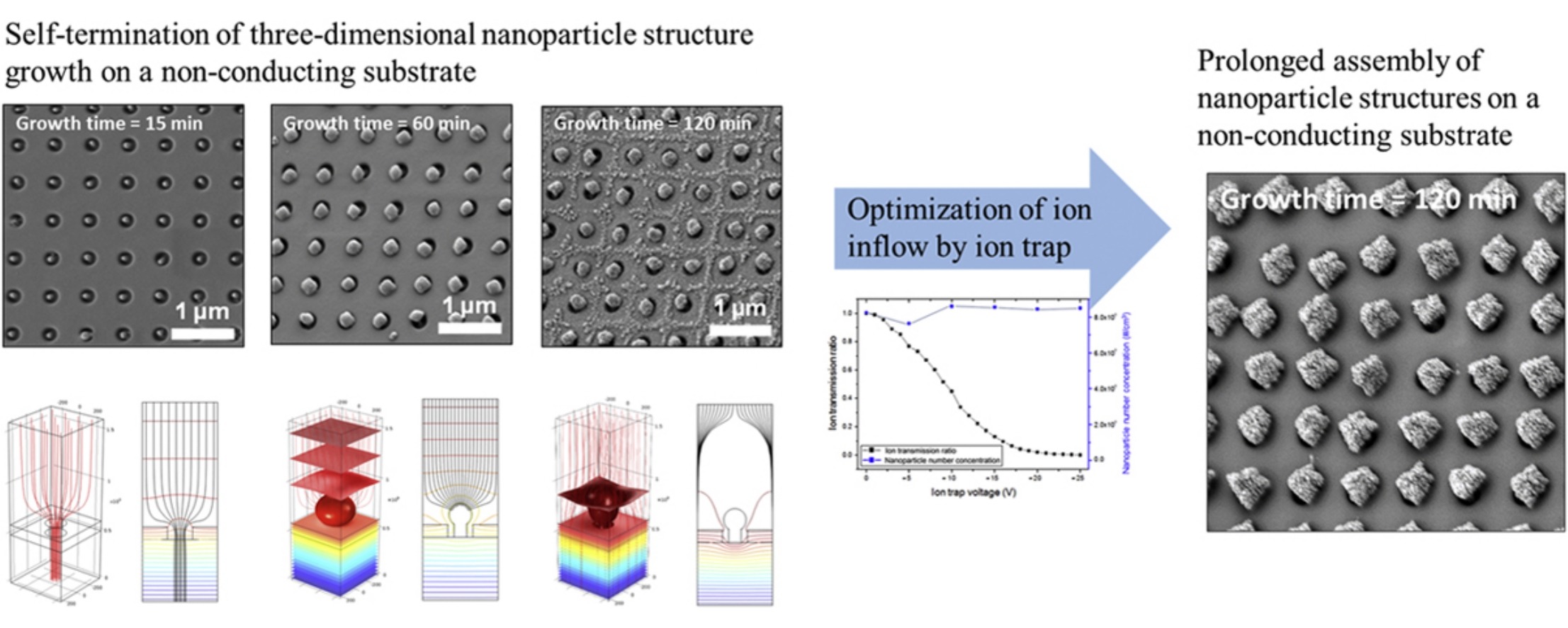

• 3D nanoparticle (NP) structures were grown on non-conducting substrates via the IAAL process.

• Electric field simulation confirmed charged NP assembly terminated after charge build up.

• An ion trap and a corona discharger were used to precisely control the ion flux.

• A prolonged assembly of NP structures on non-conducting substrate was achieved by the control.

The development of ion-assisted aerosol lithography (IAAL) has enabled fabrication of complex three-dimensional nanoparticle (NP) structures on conducting substrates. In this work, the applicability of the IAAL technique was investigated on non-conducting substrates. The NP structure growth process on a non-conducting substrate was found to self-terminate and the structures subsequently repel incoming charged NPs and scatter them away. Electric field calculations supported the experimental findings and confirmed that the electric field distortions owing to charge build-up within the structures prevented additional NP deposition thereon. To regulate the charge build-up without compromising the number of NPs available for assembly, a corona discharger and an ion trap were implemented. By varying the number of ions available in the assembly process, an optimum level of ion injection was found that allowed for a prolonged (>120 min) assembly of NP structures on non-conducting substrates without the unwanted scattering of NPs.