- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

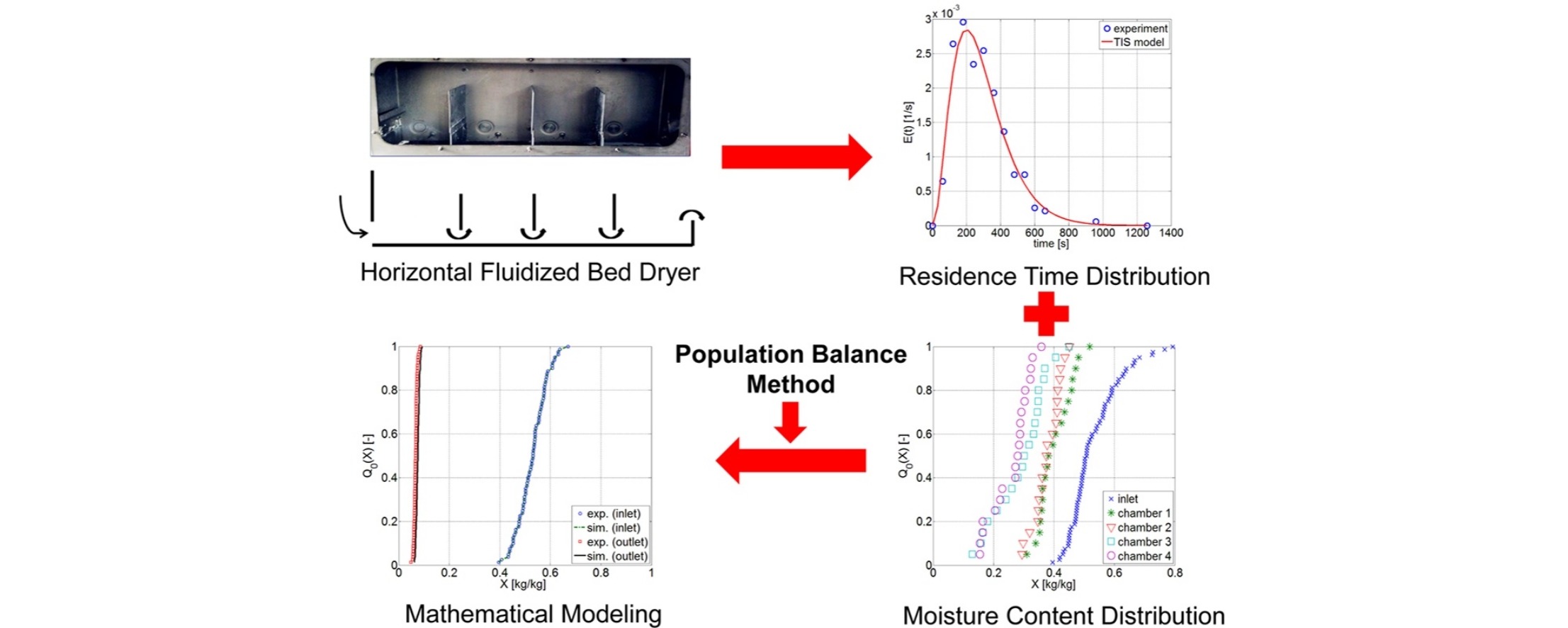

• Particle residence time and residual moisture content distributions were measured.

• A two-dimensional horizontal fluidized bed drying model was proposed.

• Parametric studies of product status under different operation conditions were conducted.

Multistage fluidized beds are frequently used for product drying in industry. One advantage of these fluidized beds is that they can achieve a high throughput, when operated continuously. In this study, γ-Al2O3 particles were dried in a pilot-scale horizontal fluidized bed, without considering any comminution effects. For each experiment, the particle moisture content distribution and residence time distribution were determined. To take into account particle back mixing in our experiments, a one-dimensional population balance model that considers particle residence time was introduced into a fluidized bed-drying model. Experimental particle residence time distributions were reproduced using a tank-in-series model. Subsequently, the moisture content distribution was implemented, as a second dimension to the population balance in this model. These two-dimensional simulations were able to describe the experimental data, especially the spread in the residual particle moisture distribution, much more accurately than one-dimensional simulations. Using this novel two-dimensional model, the effects of different operating parameters (process gas temperature, solid feed rate, superficial air velocity) on the particle moisture content distribution were systematically studied.