- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

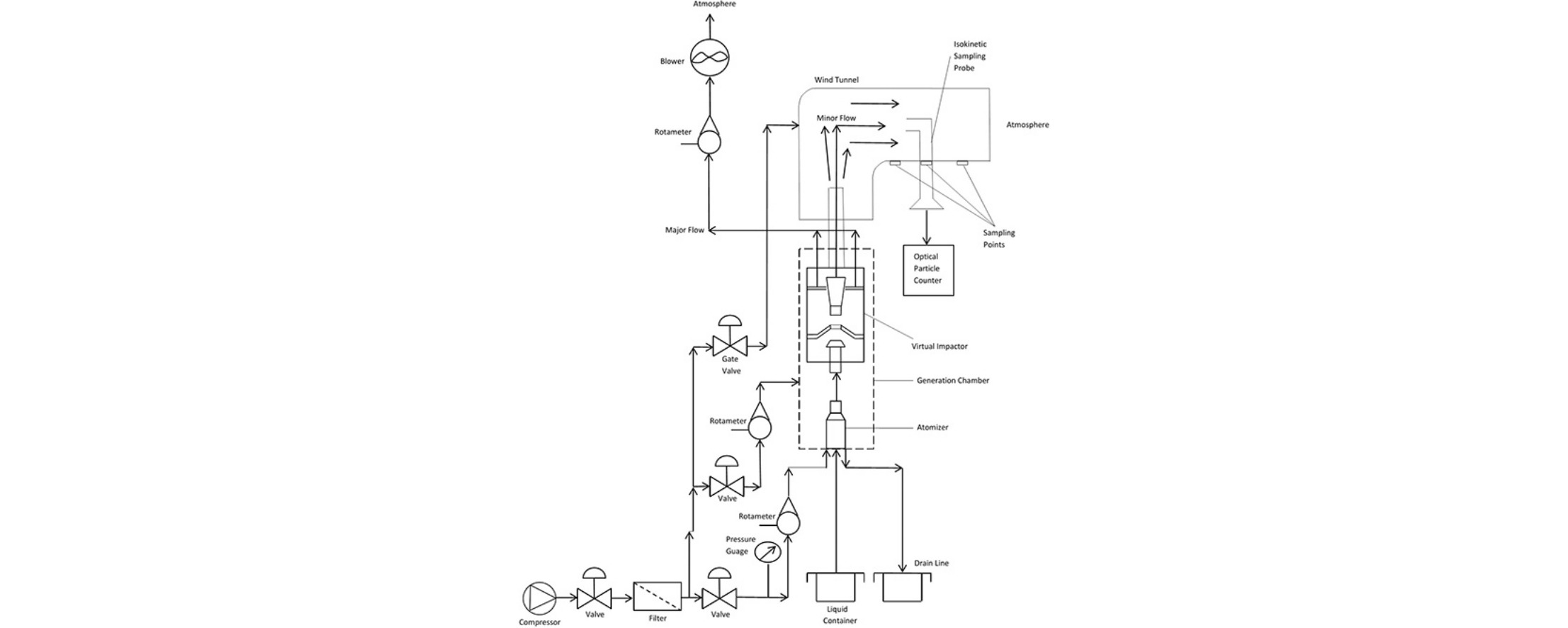

• A test monodisperse aerosol generation system was designed and constructed.

• Effects of atomizer structure, minor flow rate, and oleic acid concentration were investigated.

• Performance of the constructed aerosol generation system was tested.

Monodisperse aerosols are essential in many applications, such as filter testing, aerosol instrument calibration, and experiments for validating models. This paper describes the design principle, construction, and performance of a monodisperse-aerosol generation system that comprises an atomizer, virtual impactor, microcontroller-based isokinetic probe, wind tunnel, and velocity measurement device. The size distribution of the produced monodisperse aerosols was determined by an optical particle counter. The effects of atomizer characteristics, the rates of minor and major flow, and solution criteria were investigated. It was found that all these parameters affect the generation of monodisperse aerosol. Finally, the expected geometric standard deviation (≤1.25) of monodisperse aerosol particles was obtained with the most suitable atomizer for 10% oleic acid in ethyl alcohol solution with 5%–15% minor flow, where the ratio between the nozzle-to-probe distance and acceleration-nozzle-exit diameter was 0.66. The constructed monodisperse-aerosol-generation system can be used for instrumental calibration and aerosol research.