- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

Lei Chen, Haiyan Xu, Haixia Cui, Huidi Zhou, Hongqi Wan *, Jianmin Chen *

• Cu–Ni bimetallic nanoparticles surface-capped with dodecanethiol were successfully prepared.

• Cu–Ni bimetallic nanoparticles were highly hydrophobic and exhibited good dispersibility.

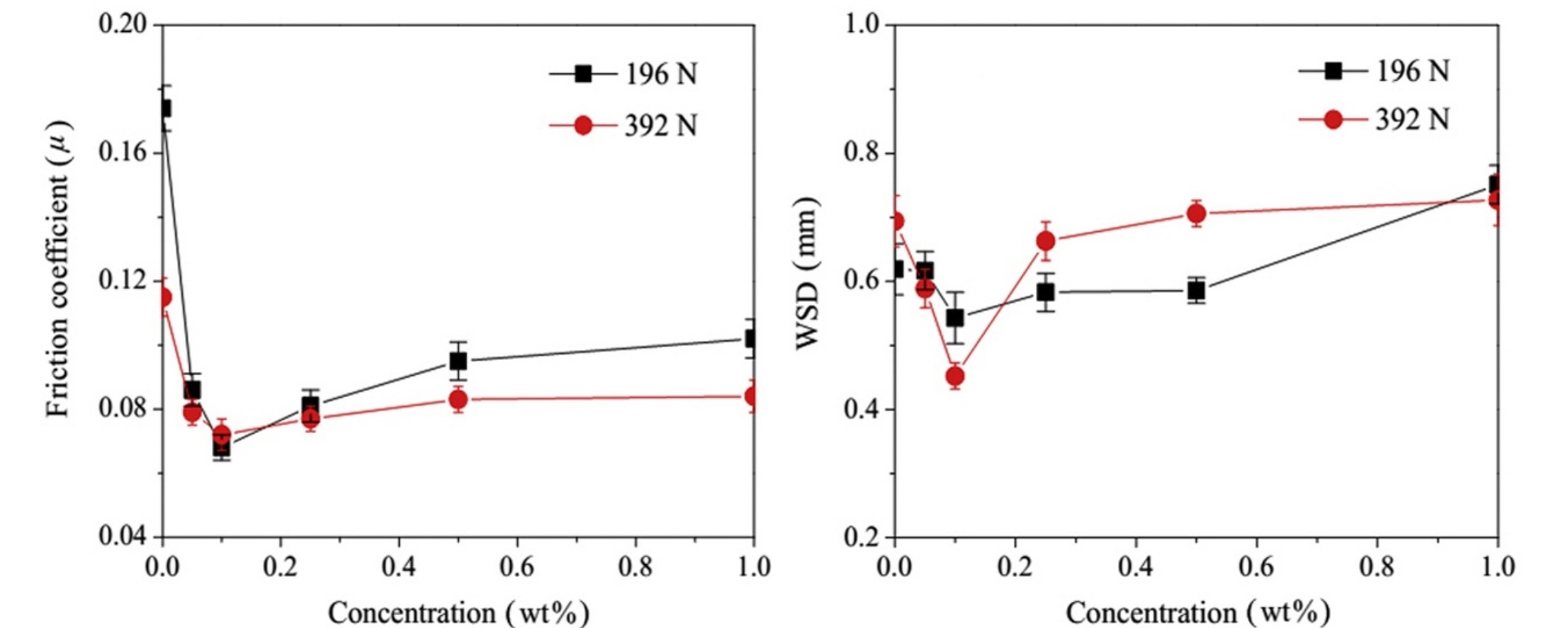

• As-prepared nanoparticles had excellent load-carrying, anti-wear and friction-reducing capacities.

• Mechanisms leading to the improvement of tribological properties were discussed.

Cu–Ni bimetallic nanoparticles surface-capped with dodecanethiol were prepared via the controlled reduction of nickel nitrate and copper nitrate in the presence of dodecanethiol as ligand and hydrazine hydrate as reductant. The morphology and structure of the Cu–Ni nanoparticles were analyzed by transmission electron microscopy, X-ray diffraction, X-ray photoelectron spectroscopy, Fourier transform infrared spectrometry, and thermal gravimetric analysis. Furthermore, the tribological properties of the Cu–Ni nanoparticles as a lubricant additive in liquid paraffin were evaluated with a four-ball machine, and the morphology and elemental composition of the worn surfaces were analyzed by three-dimensional non-contact surface profilometry and X-ray photoelectron spectroscopy, respectively. The results indicated that Cu–Ni nanoparticles prepared at a sufficient dodecanethiol concentration showed almost no signs of aggregation, and exhibited good dispersibility in various apolar solvents. The addition of the Cu–Ni nanoparticles improved the load-carrying capacity as well as friction-reducing and anti-wear abilities of liquid paraffin, attributed to the rolling effect of agglomerated Cu–Ni nanocores released by the Cu–Ni nanoparticles during sliding, and the formation of a boundary lubricating film containing tribochemical reaction products such as iron oxides and iron sulfate.