- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

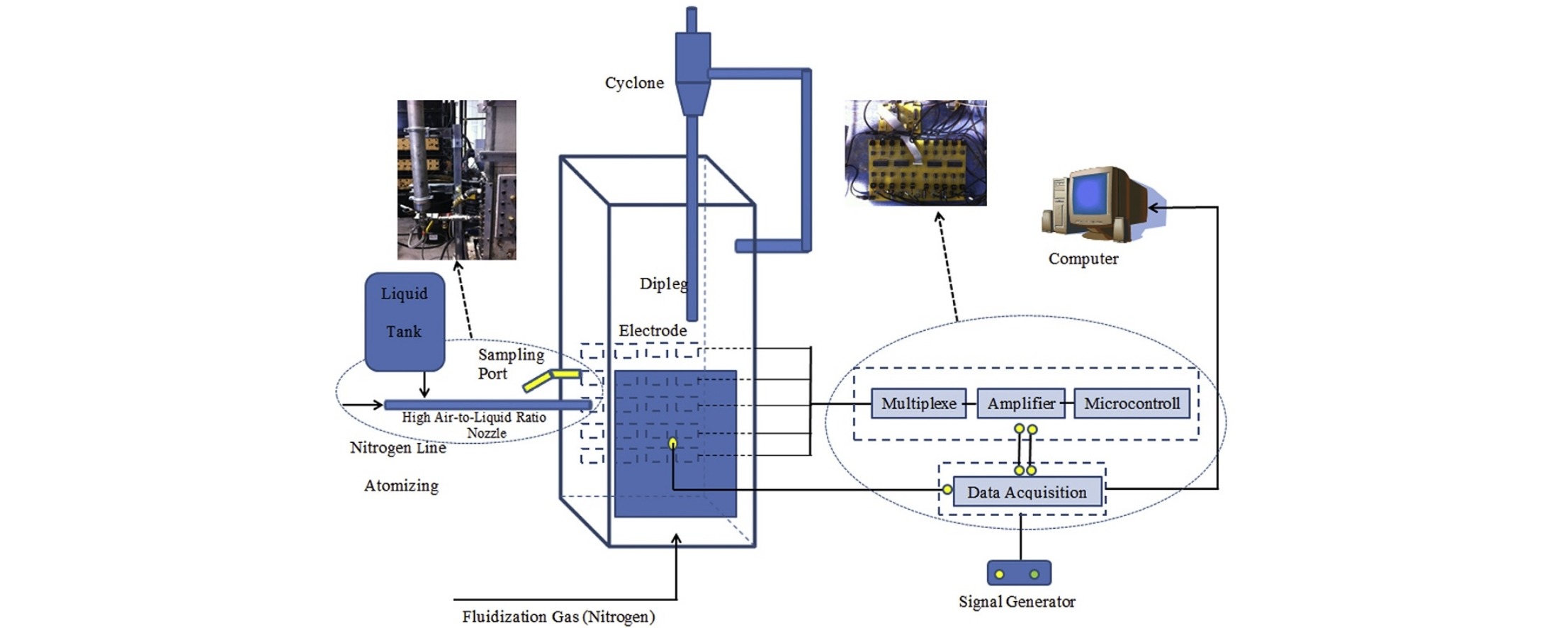

• Liquid injection experiments on a lab-scale fluidized bed were conducted.

• Particle internal porosity was found to play a major role in liquid distribution.

• The superficial gas velocity had a strong impact on the liquid distribution pattern.

• The results shed light on complexities involved in the injection zone.

Experiments were conducted on a lab-scale fluidized bed to study the distribution of liquid ethanol injected into fluidized catalyst particles. Electrical capacitance measurements were used to study the liquid distribution inside the bed, and a new method was developed to determine the liquid content inside fluidized beds of fluid catalytic cracking particles. The results shed light on the complex liquid injection region and reveal the strong effect of superficial gas velocity on liquid distribution inside the fluidized bed, which is also affected by the imbibition of liquid inside particle pores. Particle internal porosity was found to play a major role when the changing mass of liquid in the bed was monitored. The results also showed that the duration of liquid injection affected liquid–solid contact inside the bed and that liquid–solid mixing was not homogeneous during the limited liquid injection time.