- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

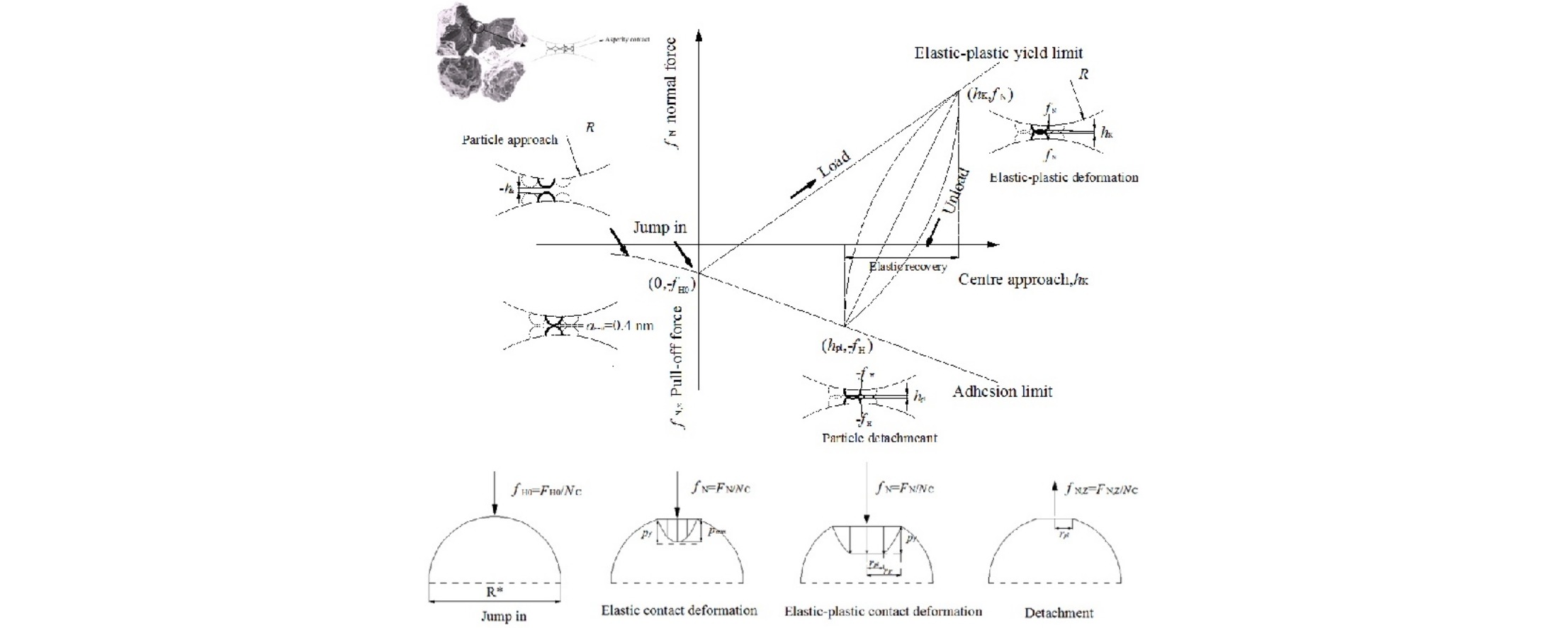

• A modified model "rough stiff particles with soft contacts" was proposed.

• Acceptable agreement was found between the predicted and measured tensile strength.

• The bulk flow properties of fuel powders were analyzed in view of micro contacts mechanics.

This work studied the mechanical properties of a series of industrial fuel powders: bituminite, lignite, and petroleum coke. Sieved cuts of these powders were assessed and the flow properties of each sample were used to calculate tensile strengths as functions of consolidation stress. In addition, BET surface areas and dispersive surface energies were estimated from surface energy analysis. To analyze the bulk flow properties of these fuel powders in terms of micro-contact mechanics, the fundamentals of fuel powder adhesion and consolidation were reconsidered based on the "stiff particles with soft contacts" model proposed by Tomas. In the present work, a multi-contact concept was introduced to account for the irregular shapes of actual particles. This modified model was based on elastic–plastic contact deformation theory and was employed to describe the contact between rough particles and to estimate the associated inter-particle forces. The results were used in conjunction with the Rumpf approach to relate the isostatic tensile strength to the degree of consolidation. Applying average values for the powder compressibility parameters allowed the model to be used for predictive purposes, and an acceptable level of agreement was found between predicted and measured tensile strengths.