- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• The critical time step for rotational resistance models was derived.

• Analytical solutions for model validation scenarios were derived.

• Transition from rolling to sliding at contact points was identified.

• The limitations of rotational resistance models were discussed.

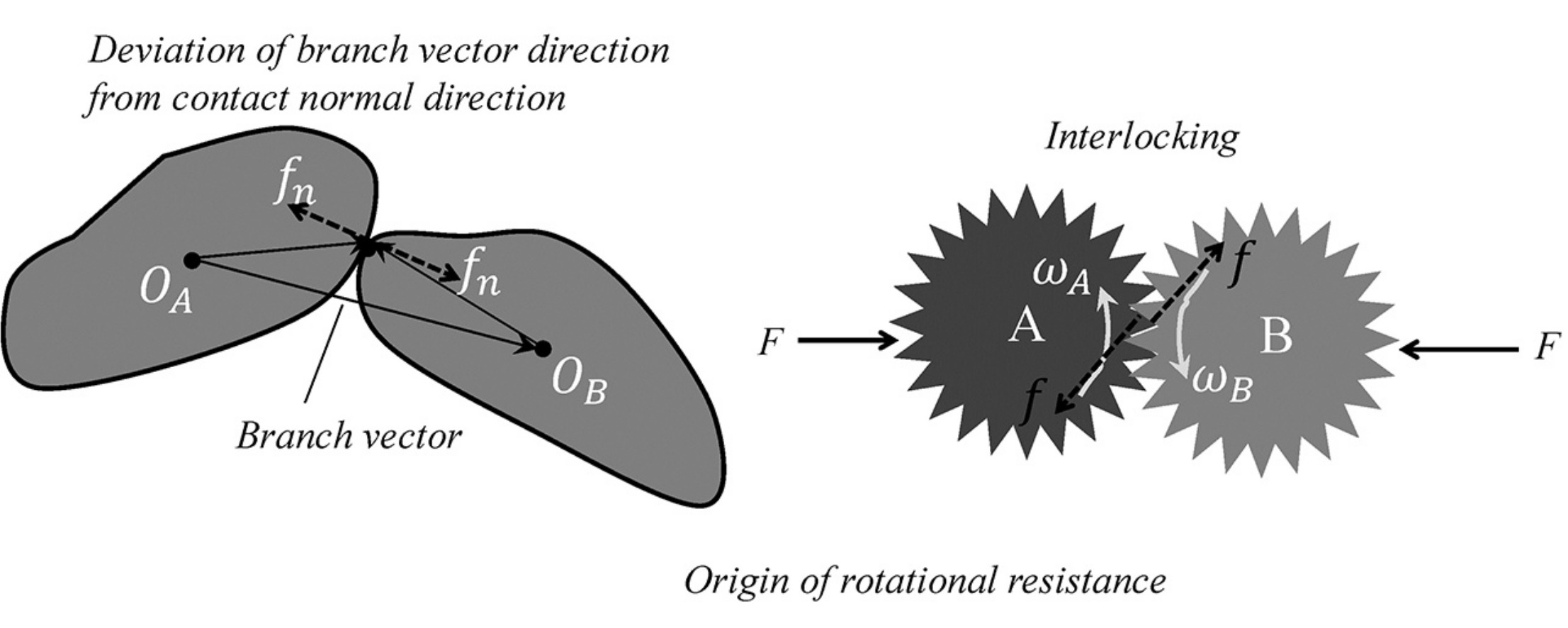

Contact models that simulate rotational resistance at particle contacts have been proposed as a means to capture the effect of shape in DEM simulations. This contribution critically explores some key issues related to the implementation of rotational resistance models; these include the need for physically meaningful model parameters, the impact of the model on the overall numerical stability/critical time increment for the DEM model, model validation, and the assessment of model performance relative to real physical materials. The discussion is centred around a rotational resistance model that captures the resistance provided by interlocking asperities on the particle surface. An expression for the maximum permissible integration time step to ensure numerical stability is derived for DEM simulations when rotational resistance is incorporated. Analytical solutions for some single-contact scenarios are derived for model validation. The ability of this type of model to provide additional fundamental insight into granular material behaviour is demonstrated using particle-scale analysis of triaxial compression simulations to examine the roles that contact rolling and sliding have on the stability of strong force chains.