- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• The thickness of low density layer affected the final settling time of high density particles.

• Coal swarm properties would affect the fluidization characteristic in the fluidized bed.

• The feeding mass fraction of coal should be limited to 10% and 13% respectively.

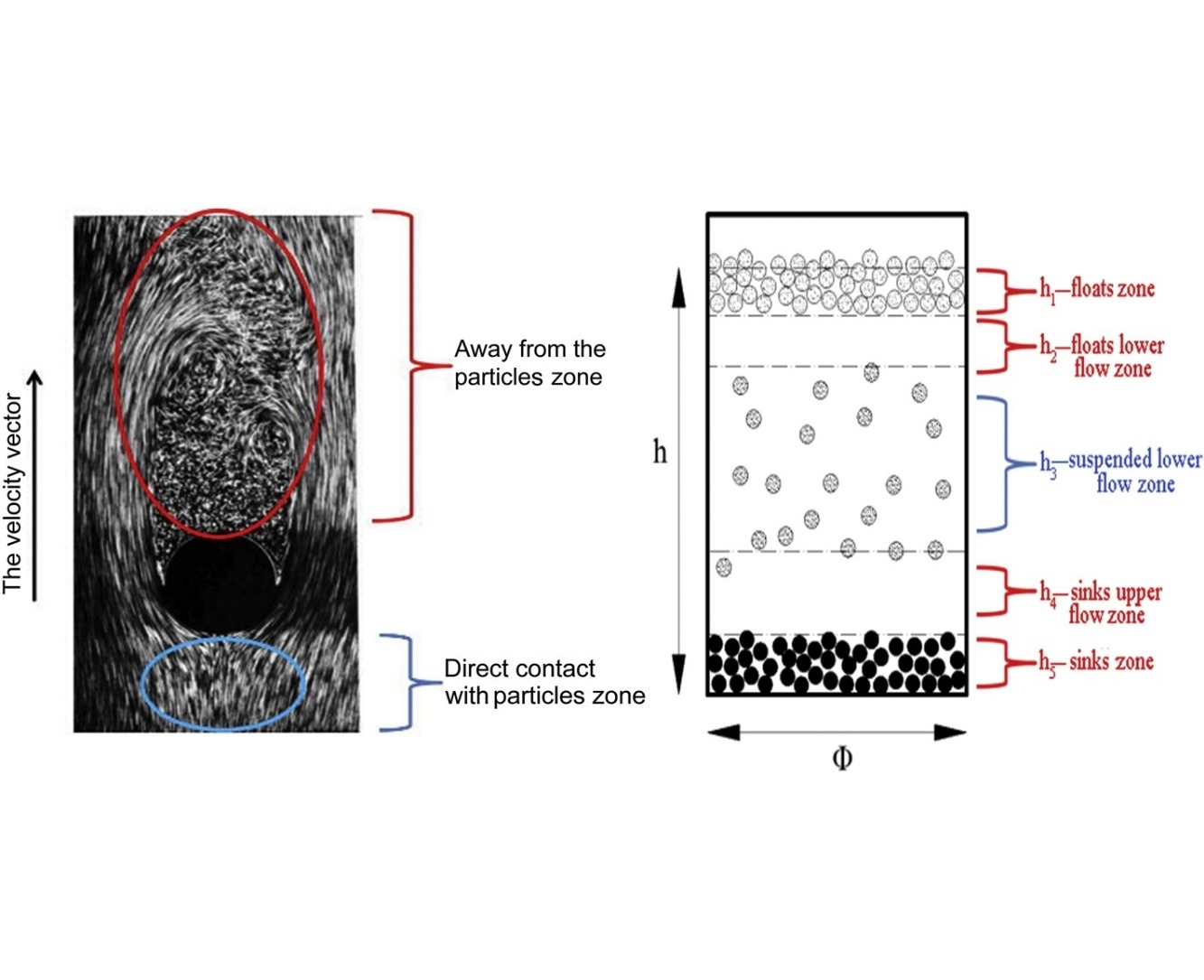

This paper analyzes the influence of different coal mass fraction in an air dense medium fluidized bed (ADMFB). The effect of the low density particles layer on heavy sedimentation increased with increasing material layer thickness. The thickness of the low density particles layer also affected the final settling time of the high density particles. Increasing the thickness of the low density particles layer by Δh provoked an increase in the settling of high density particles that was related to their diameter (Δh/D). The pressure gradient across the bed was lower than that observed for the control experiment, which had only the dense material, owing to a decrease in the pressure gradient in Zones 1 and 5 (at the top and bottom of the bed, respectively). Introducing different coal sizes resulted in different fluidization environments, particle accumulation layers, and changes to the surrounding zone. However, the influence of the coal particles on the local bed characteristics was related to its concentration. The feeding mass fraction of 6–13 mm size and 13–25 mm size coal should be limited to10% and 13%, respectively. The ranges of possible deviation were found to be 0.08–0.15 and 0.07–0.10 for the respective samples.