- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

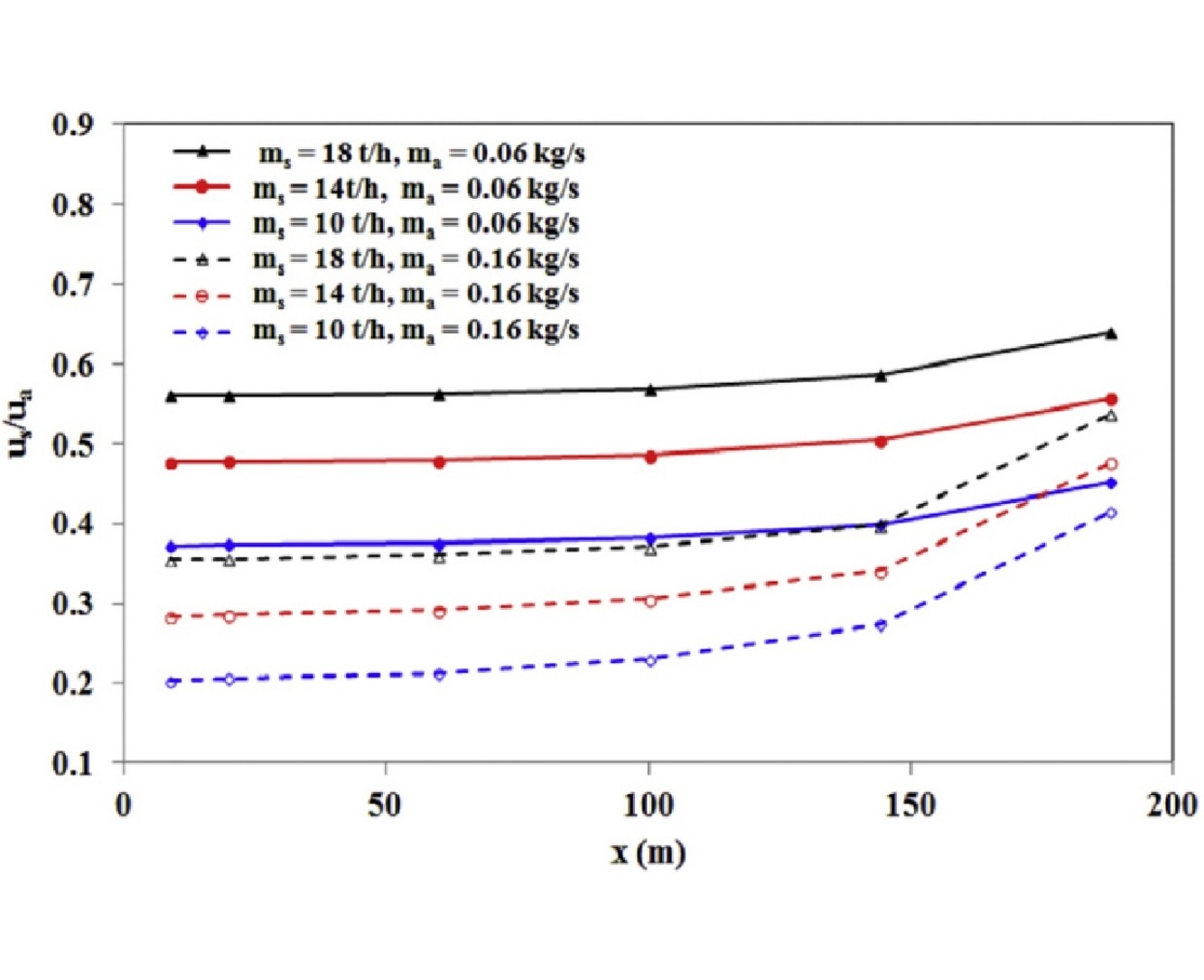

• Numerical simulations showed increased particle and actual air velocities along flow direction.

• New model for solids friction factor was developed using particle-to-air velocity ratio.

• New model was evaluated for scale-up accuracy in longer and larger pipeline.

Accurate prediction of the solids friction factor through horizontal straight pipes is important for the reliable design of a pneumatic conveying system, but it is a challenging assignment to date because of the highly concentrated, turbulent, and complex nature of the gas–solids mixture. Power-station fly ash was transported through different pipeline configurations. Numerical simulation of the dense-phase pneumatic conveying systems for three different solids and two different air flow rates have shown that particle and actual gas velocities and the ratio of the two velocities increases in the flow direction, whereas the reverse trend was found to occur for the solids volumetric concentration. To develop a solids friction-factor model suitable for dense-phase flow, we modified an existing pure dilute-phase model by incorporating sub-models for particle and actual gas velocities and impact and solids friction factor. The solids friction-factor model was validated by using it for scale-up predictions for total pipeline pressure drops in longer and larger pipes and by comparing experimental and predicted pneumatic conveying characteristics for different solids flow rates. The accuracy of the prediction was compared with a recently developed two-layer-based model. We discussed the effect of incorporating the particle and actual gas velocity terms in the solids friction-factor model instead of superficial air velocity.