- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

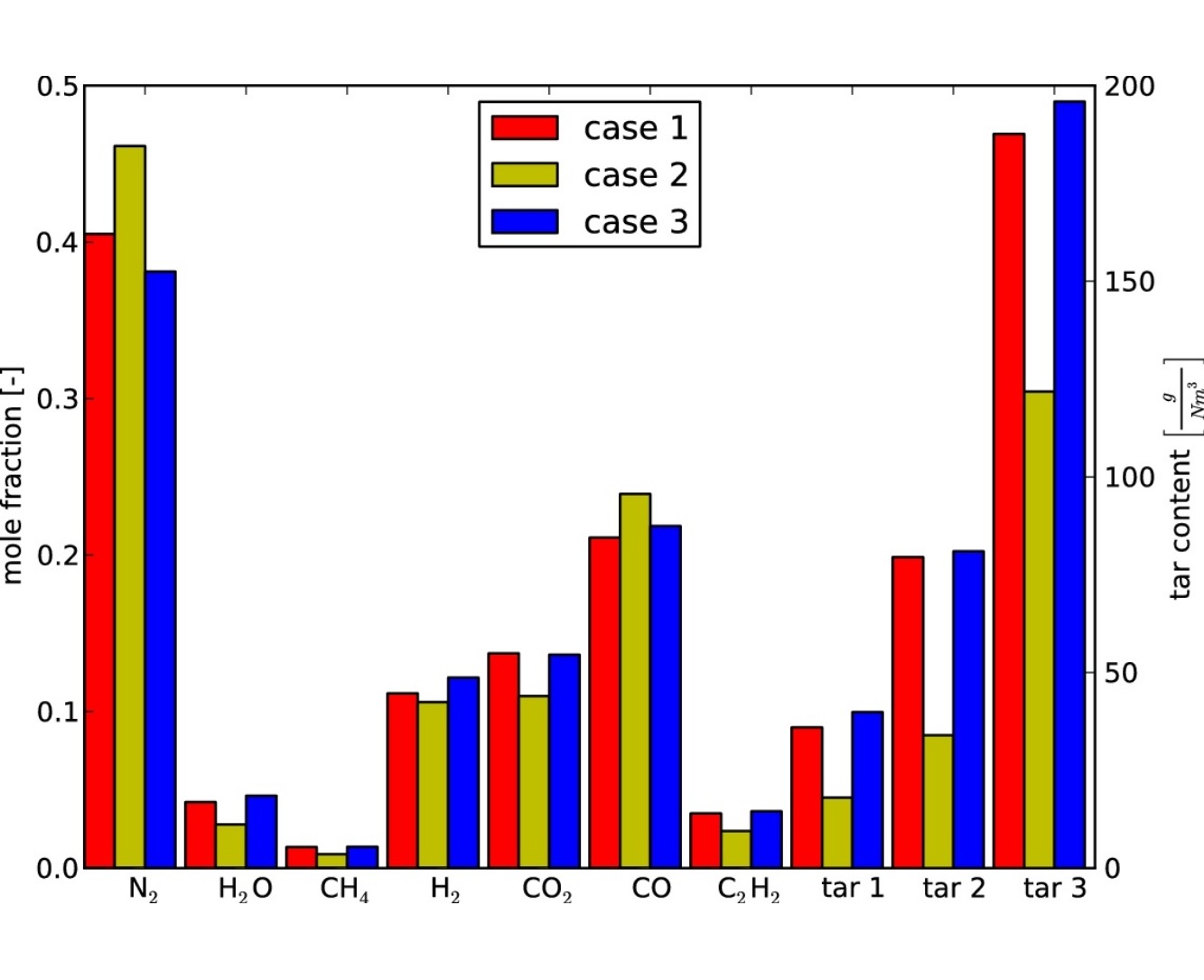

• Euler–Lagrangian simulation of wood gasification in a charcoal bed was performed.

• Long time simulation exhibited the various temporal behavior of the phases.

• Tar concentrations at the reactor outlet strongly depended on model settings.

• Particle contact properties showed minor influence on the results.

A Euler–Lagrangian simulation was employed for a comprehensive parameter study of wood gasification in a fluidized charcoal bed. The parameters that were varied include the initial bed temperature, fuel mass flow rate, inert tar fraction, and kinetic energy losses caused by particle–particle and particle–wall collisions. The results of each parameter variation are compared with a base scenario, previously described in detail in Part I of this study (Gerber & Oevermann, 2014). The results are interpreted by comparing the reactor outlet temperature, averaged particle temperature, overall wood mass, overall charcoal mass, concentrations of several gaseous species, and axial barycenter data for particles obtained with different sets of parameters. The inert tar fraction and fuel mass flow rate are the most sensitive parameter, while the particle–particle and particle–wall contact parameters have only a small impact on the results. Increasing the reactive tar components by 19% almost doubled the amount of reactive tars at the reactor outlet, while decreasing the restitution coefficients of the particle collisions by 0.2 results in higher overall gas production but almost no change in bed height. Herein, our numerical results are discussed in detail while assessing the model restrictions.