- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

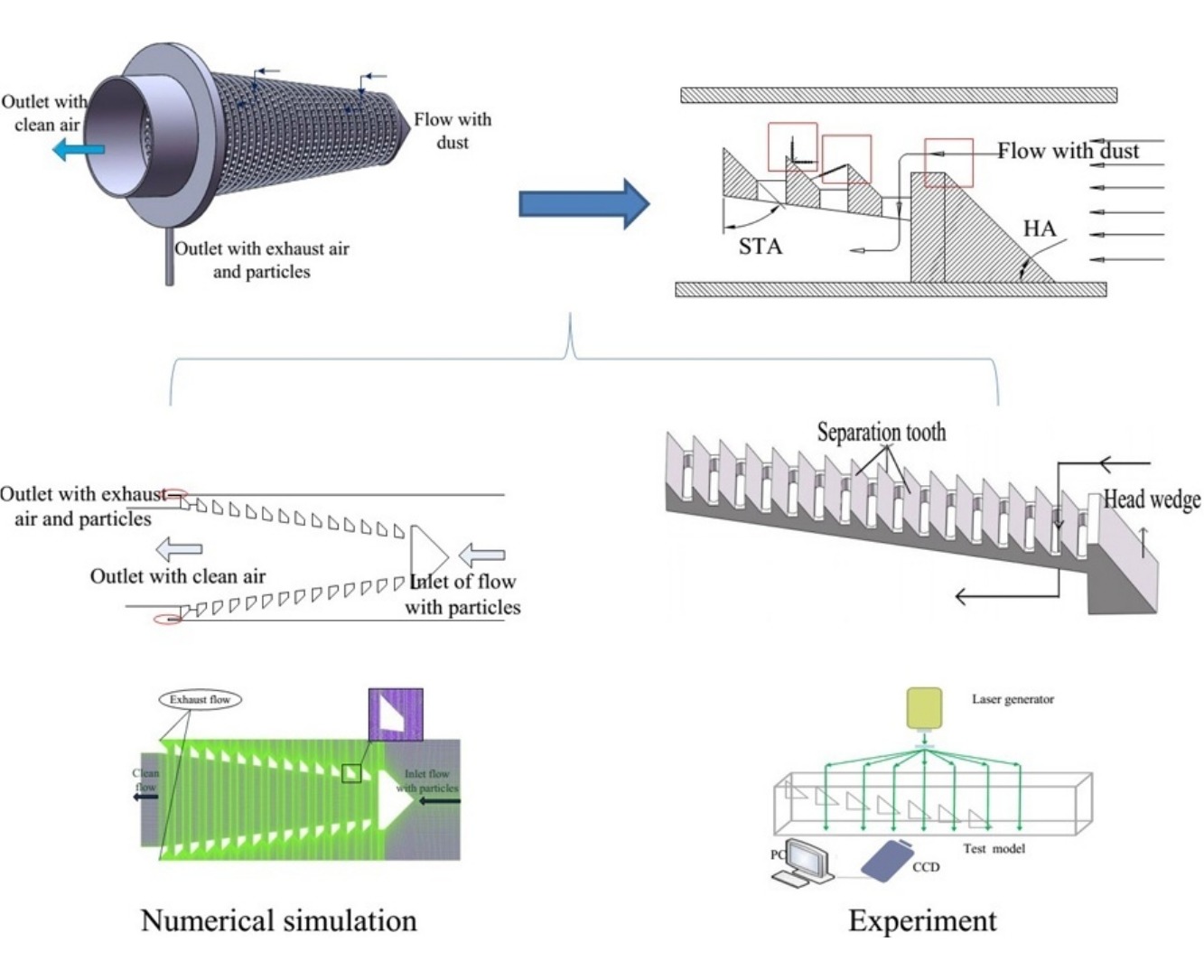

• Particle trajectories in the separator were measured using particle-trajectory imaging method.

• Changes of particle characteristic angles under different conditions were analysed based on DPM.

• The characteristics of particle motion within the separator were modelled.

• Changes in separation efficiency, pressure loss and exhaust gas flow rate were calculated.

The presence of solid particles in the flow of hypersonic wind tunnels damages the appearance of the experiment models in the wind tunnel and influences the accuracy of experimental results. The design of a highly efficient gas–solid separator was therefore undertaken. Particle trajectory imaging methods were used to measure trajectories under different conditions. The flow field and particle movement characteristics for different head angles (HAs) and separation tooth angles (STAs), inlet velocities, and the exhaust gas outlet pressures in the separator, were calculated using simulations based on the discrete phase model. The particle separation efficiency, pressure loss, and flow loss resulting from different structural parameters were also studied. In line with experimental observations, the characteristic angle of particle movements in the separator and the separation efficiency of the separator were found to increase with decreasing HA and with increasing STA. Separation efficiency improves with increasing inlet velocity and with increasing negative pressure of the exhaust gas outlet; however, the corresponding pressure loss and the flow rate of the waste gas also increased.