- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A new approach for simulating the formation of a froth layer in slurry bubble column was proposed.

• The effects of hydrophilic particles on bubble dynamics in a multiphase system were proposed.

• Effects of particle size and concentration on gas holdup and coalescence efficiency were studied.

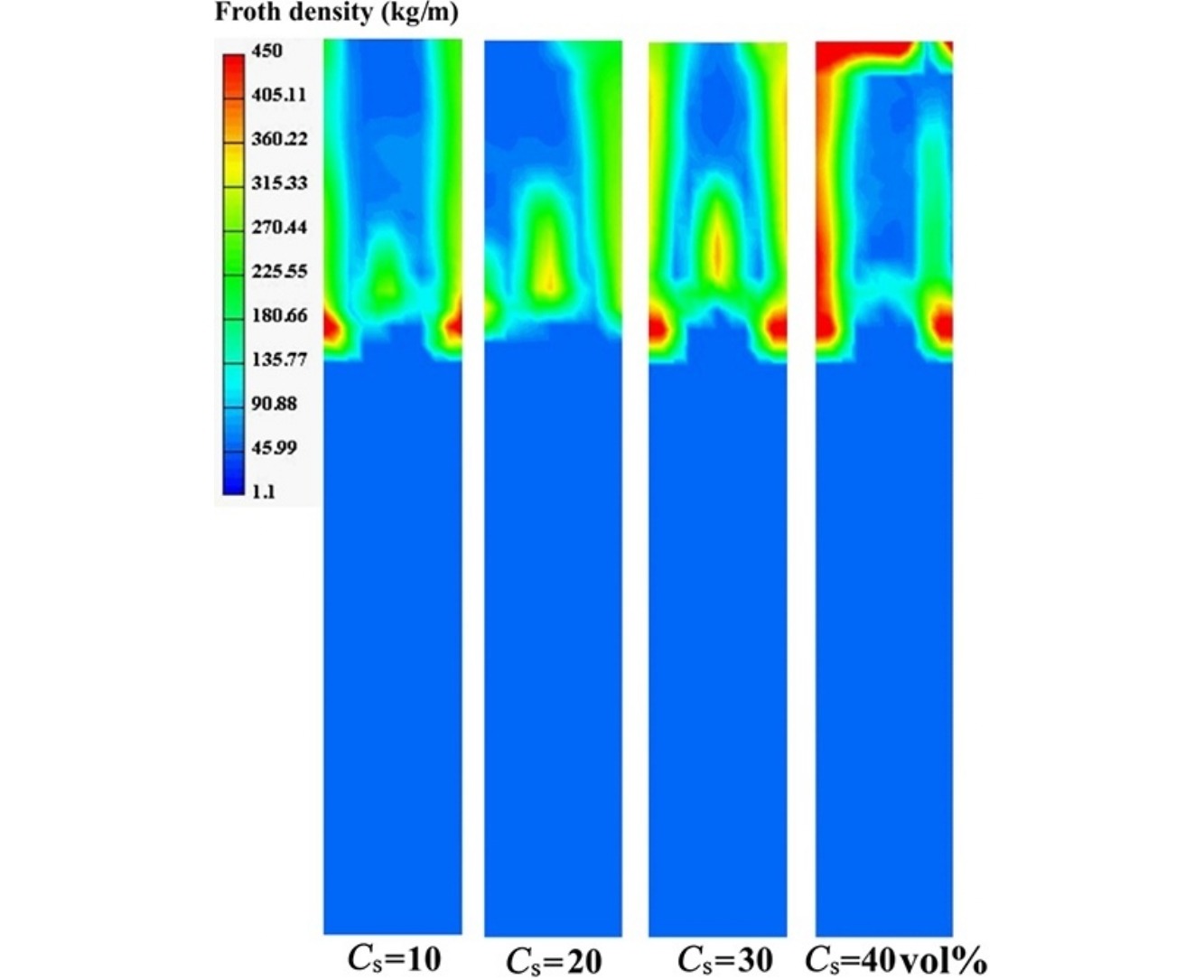

• Froth density for froth with different particles size was predicted.

A new approach for simulating the formation of a froth layer in a slurry bubble column is proposed. Froth is considered a separate phase, comprised of a mixture of gas, liquid, and solid. The simulation was carried out using commercial flow simulation software (FIRE v2014) for particle sizes of 60–150 μm at solid concentrations of 0–40 vol%, and superficial gas velocities of 0.02–0.034 m/s in a slurry bubble column with a hydraulic diameter of 0.2 m and height of 1.2 m. Modelling calculations were conducted using a Eulerian–Eulerian multiphase approach with k–ε turbulence. The population balance equations for bubble breakup, bubble coalescence rate, and the interfacial exchange of mass and momentum were included in the computational fluid dynamics code by writing subroutines in Fortran to track the number density of different bubble sizes. Flow structure, radial gas holdup, and Sauter mean bubble diameter distributions at different column heights were predicted in the pulp zone, while froth volume fraction and density were predicted in the froth zone. The model was validated using available experimental data, and the predicted and experimental results showed reasonable agreement. To demonstrate the effect of increasing solid concentration on the coalescence rate, a solid-effect multiplier in the coalescence efficiency equation was used. The solid-effect multiplier decreased with increasing slurry concentration, causing an increase in bubble coalescence efficiency. A slight decrease in the coalescence efficiency was also observed owing to increasing particle size, which led to a decrease in Sauter mean bubble diameter. The froth volume fraction increased with solid concentration. These results provide an improved understanding of the dynamics of slurry bubble reactors in the presence of hydrophilic particles.