- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

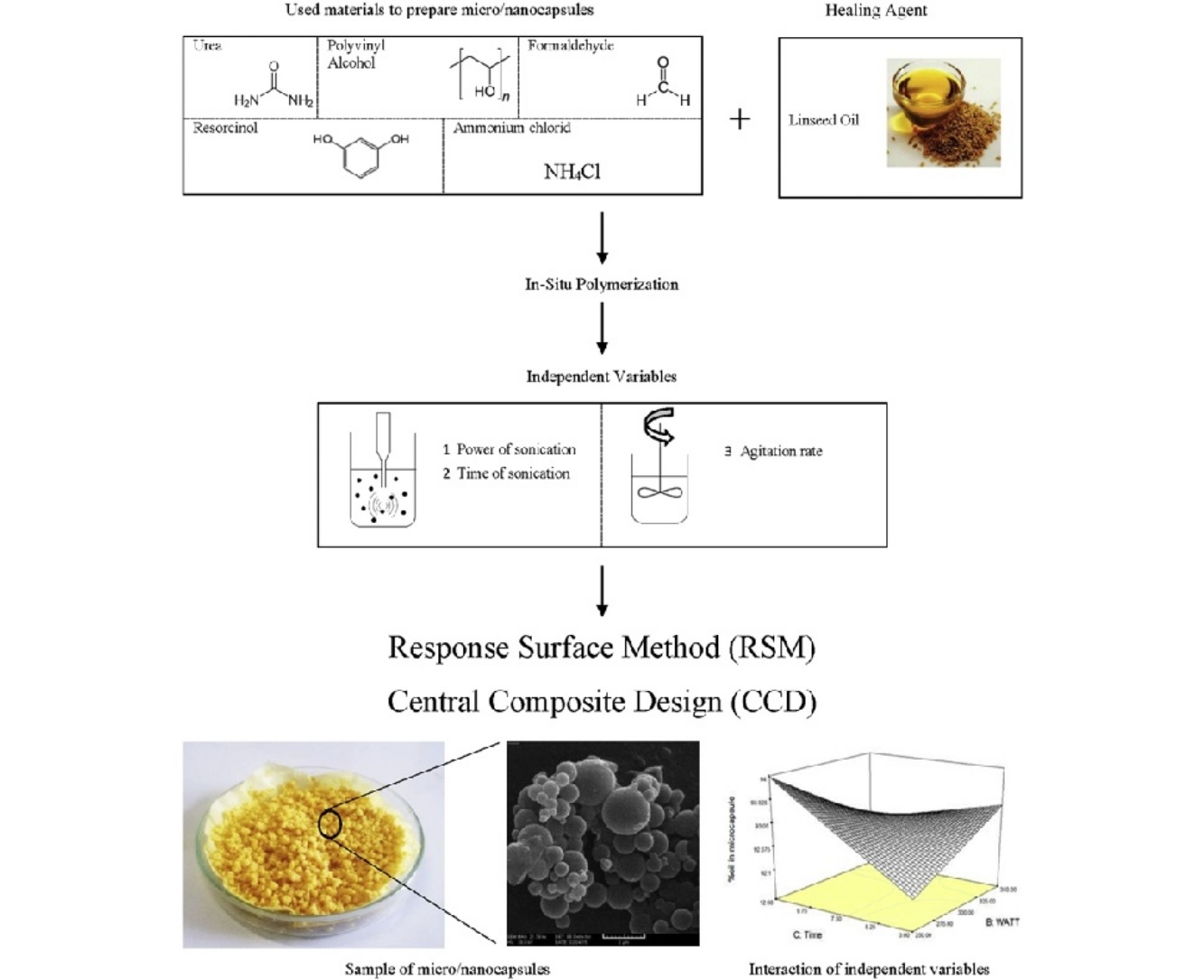

• Parameters affecting in-situ microencapsulation process of self-healing material were studied.

• Models for optimizing synthesized microcapsules were developed.

• Self-healing and anti-corrosion properties of micro/nanocapsule loaded epoxy were evaluated.

Micro/nanocapsules of urea–formaldehyde resin loaded with linseed oil, which are a self-healing agent in glass flake epoxy anti-corrosion paint, were prepared using a combination of ultrasonic homogenization and in-situ polymerization. The main objective of this study was to model and optimize the microencapsulation process. Five-level central composite design was used to design, model, and optimize the microencapsulation process. A quadratic model was constructed to show the dependency of the percentage of encapsulated linseed oil and capsule size, as model responses, on the studied independent variables (the rotational speed of the agitator and the power and duration of sonication). Analysis of variance showed that all of the variables have significant effects on the encapsulated linseed oil percentage, while the rotational speed of the agitator and sonication time is effective variables for controlling the capsule size. Under the determined optimum conditions, a maximum encapsulated linseed oil percentage (ELO%) of 93.9% and a minimum micro/nanocapsule size of 0.574 μm were achieved at 594 rpm agitation, 350 W sonication power, and 3 min sonication time. Validation of the model was performed. The percentage relative errors between the predicted and experimental values of the ELO% and micro/nanocapsule size are 1.28% and 3.66%, respectively. The efficacy of the optimum micro/nanocapsules in healing cracks in a glass flake epoxy paint and corrosion protection was investigated by the salt spray test and Tafel polarization technique.