- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

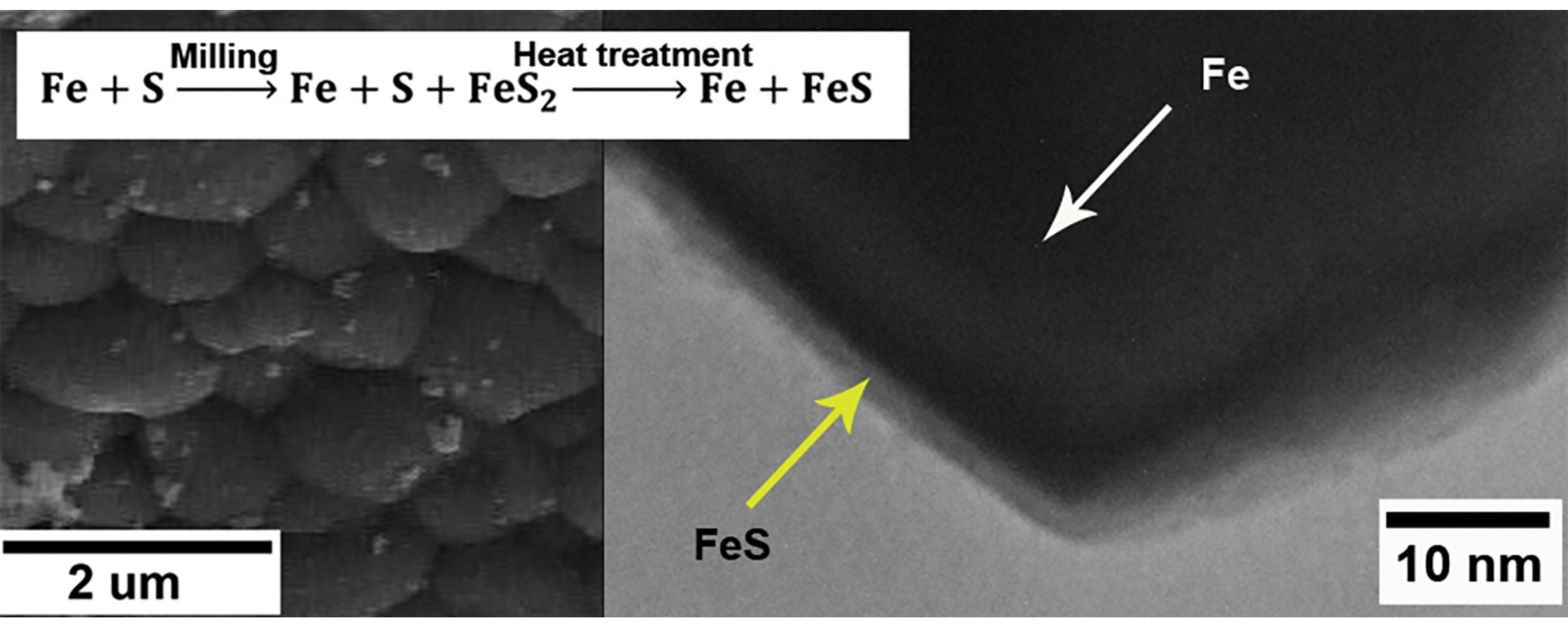

• Fe/FeS core/shell nano-structure was synthesized by mechano-thermal method.

• Approximately 2 nm of FeS shell was formed on the Fe core.

• Mechanism of transformation was studied by differential scanning calorimetry.

• Mechanical activation and NaCl addition led to decrease of Ms value.

A novel method was used to prepare a nano-structured 32 wt% Fe/FeS core/shell powder via a mechano-thermal route by 1-h heat treatment of a mechanically activated powder mixture of Fe and S. The structural and microstructural characteristics, formation mechanism, magnetic properties, and photocatalytic activity of the powder were studied by X-ray diffraction, field emission scanning electron microscopy, transmission electron microscopy, surface area analysis, differential scanning calorimetry, vibrating sample magnetometry, and UV–vis spectrophotometry. A detailed study of the mechanism of transformation showed that during the heat treatment process, an FeS2 phase was formed as the intermediate product. In the final product, an FeS shell approximately 2 nm in thickness was formed on the Fe core. In the presence of NaCl as a process control agent, the particle size decreased and the size distribution became more uniform. Mechanical activation and NaCl addition together led to a decrease of the saturation magnetization from 82 to 74 emu/g. The photocatalytic activity of the powder in the degradation of methylene blue was 50%.