- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

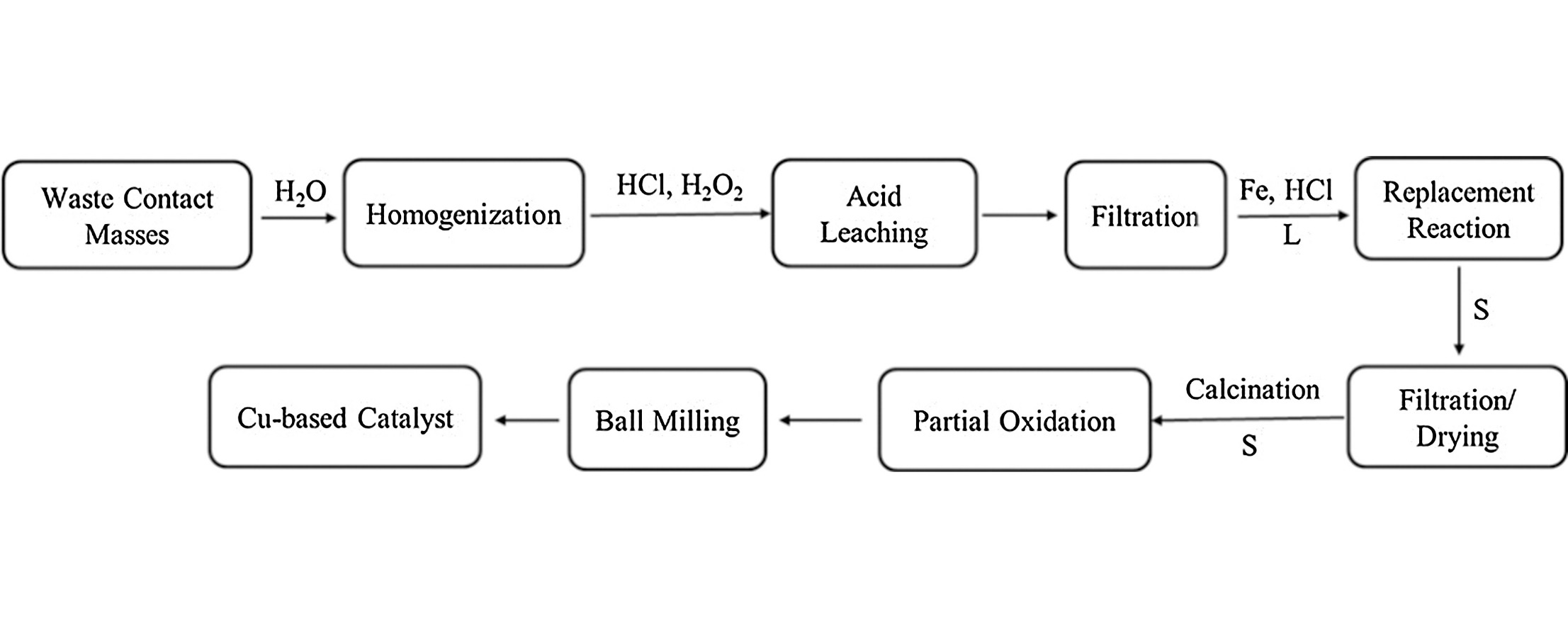

• Multicomponent Cu-based catalysts were prepared from industrial waste contact masses (WCMs).

• Cu powder was recovered via acid leaching, followed by partial oxidation and ball milling.

• Optimized Cu–Cu2O–CuO exhibited good (CH3)2SiCl2 selectivity when re-used in Rochow synthesis.

In this work, we report a simple and inexpensive approach to synthesize effective multicomponent Cu–Cu2O–CuO catalysts for the Rochow process from industrial waste contact masses (WCMs). WCMs from the organosilane industry were treated with acid followed by reduction with metallic iron powder. The obtained copper powder was then subjected to controlled oxidation in air at different temperatures, followed by ball milling. The orthogonal array approach was applied to optimize this process, and the stirring speed and pH were found to significantly affect the leaching ratio and copper yield, respectively. When used for the Rochow process, the optimized ternary Cu–Cu2O–CuO catalyst greatly enhanced the dimethyldichlorosilane selectivity and Si conversion compared with Cu–Cu2O–CuO catalysts prepared without ball milling, bare Cu catalysts, and Cu–Cu2O–CuO catalysts with different compositions. This could be attributed to their small particle size and the strong synergistic effect among the multiple components in the catalyst with the optimized composition.