- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

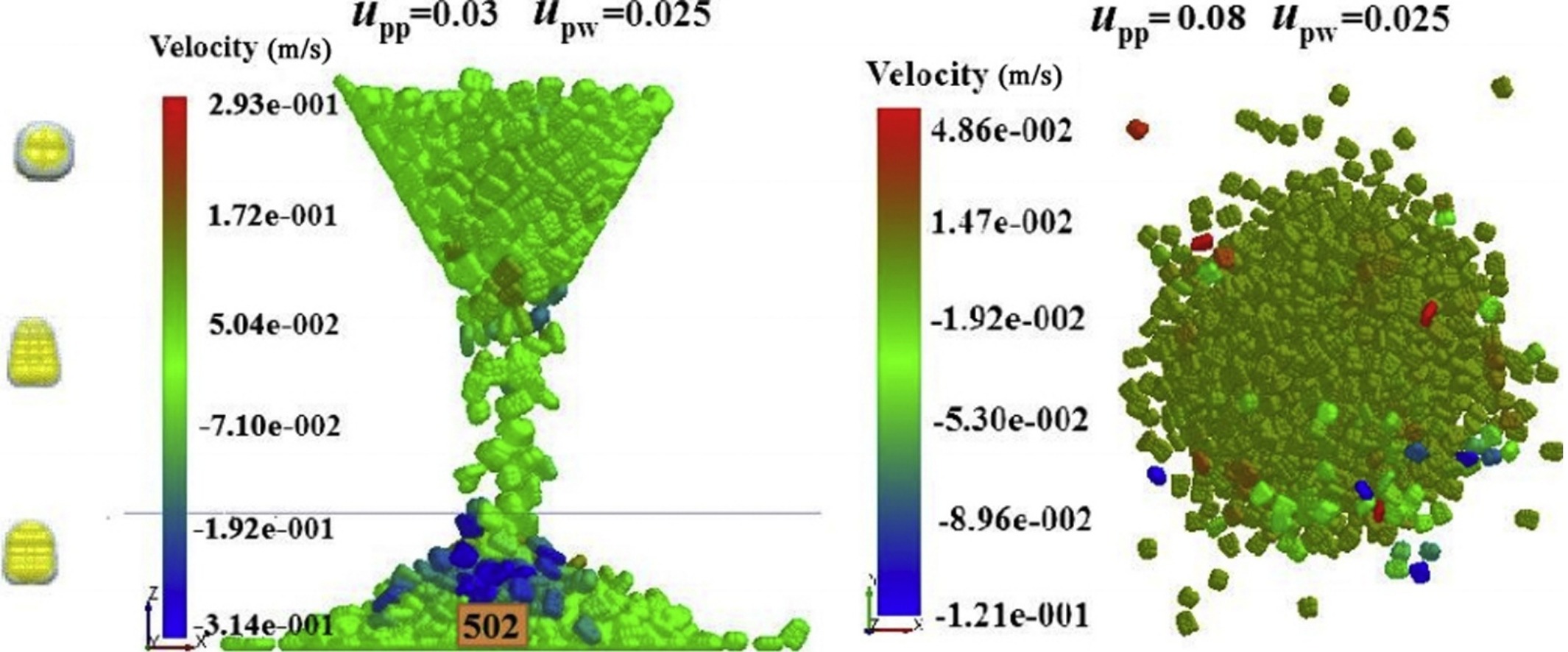

• The coefficient of rolling friction (CORF) of different shaped maize particles was studied.

• The CORF was determined by a combination of simulation and test.

• The golden section method was used to reduce the optimal coefficient range.

The coefficient of rolling friction is an important physical property of a maize particle. It is difficult to obtain the value of this coefficient because of the irregular shape of maize particles. This paper describes an approach that combines the discrete-element method (DEM) and a physical test to determine the coefficient of rolling friction of irregularly shaped maize particles. A novel test platform was used to obtain the maize particle's coefficient of restitution and the coefficient of static friction. EDEM software (DEM-Solutions, United Kingdom) was used to simulate the accumulation of maize particles on particles and on a zincified plate. The golden-section method was used to determine the range of the maize particle's coefficient of rolling friction. A single-factor test was used to determine the relationship between the maize particle's coefficient of rolling friction and their angle of repose. The results obtained from the EDEM simulation were compared with physical test results to determine the intergranular coefficient of rolling friction and the coefficient of rolling friction between maize particles and the zincified plate. Our study demonstrates that the angle of repose increases linearly with the coefficient of rolling friction of maize particles. The effect of the coefficient of rolling friction on the particle movement is studied. The physical verification test indicates that the obtained rolling friction of the maize particles is accurate. The findings of this paper provide a theoretical basis for maize-processing machine design and a discrete-element study of the motion of maize particles inside such machines.