- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

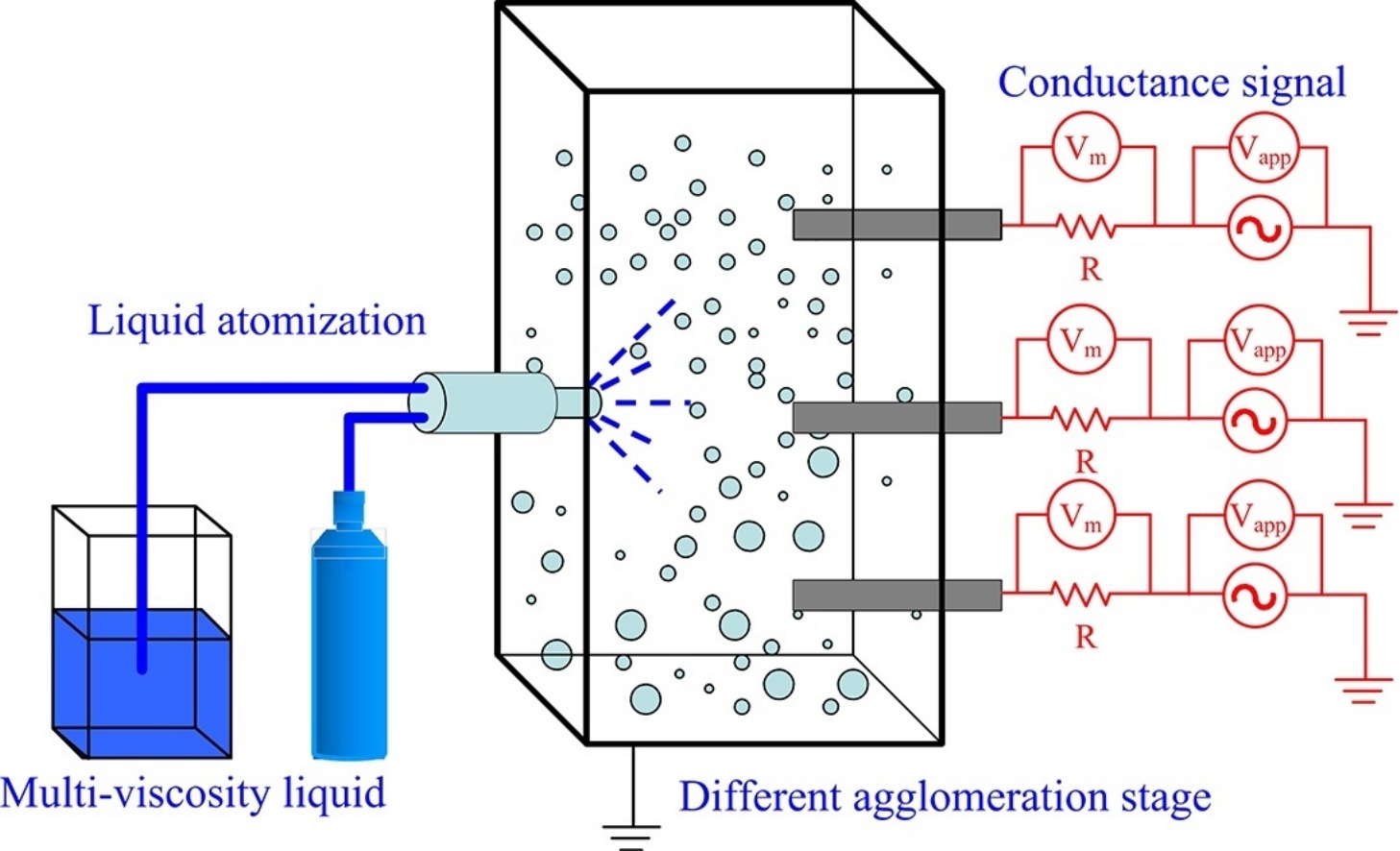

• Bed material agglomeration during injecting multi-viscosity liquid jets was studied.

• Water-sand system at room temperature was used to simulate the hot bitumen-coke system.

• Different agglomeration stages were identified in a fluidized bed based on conductance method.

Fluidized bed agglomeration is an important and challenging problem for thermal cracking in fluid cokers. A low coker temperature can be problematic because the bitumen is injected into the fluidized bed with a different viscosity, resulting in formation of agglomerates of varying sizes, which slows the cracking reactions. In the present study, the bed material agglomeration process during nozzle injection of multiviscosity liquid was investigated in a fluidized bed operated at different mass ratios of the atomization gas to the liquid jets (GLR = 1%–3.5%) and gas velocities (3.9Umf and 5.9Umf) based on a conductance method using a water–sand system to simulate the hot bitumen–coke system at room temperature. During the tests of liquid-jet dispersion throughout the bed, different agglomeration stages are observed at both gas velocities. The critical amount of tert-butanol in the liquid jets that could lead to severe agglomeration of the bed materials (poor fluidization) at GLR = 1% is about 10 wt% at the low fluidizing gas velocity (3.9Umf) and 18 wt% at the high gas velocity (5.9Umf). This study provides a new approach for on-line monitoring of bed agglomeration during liquid injection to guarantee perfect contact between the atomized liquid and the bed particles.