- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Novel multistage solid–liquid circulating fluidized bed (SLCFB) was proposed.

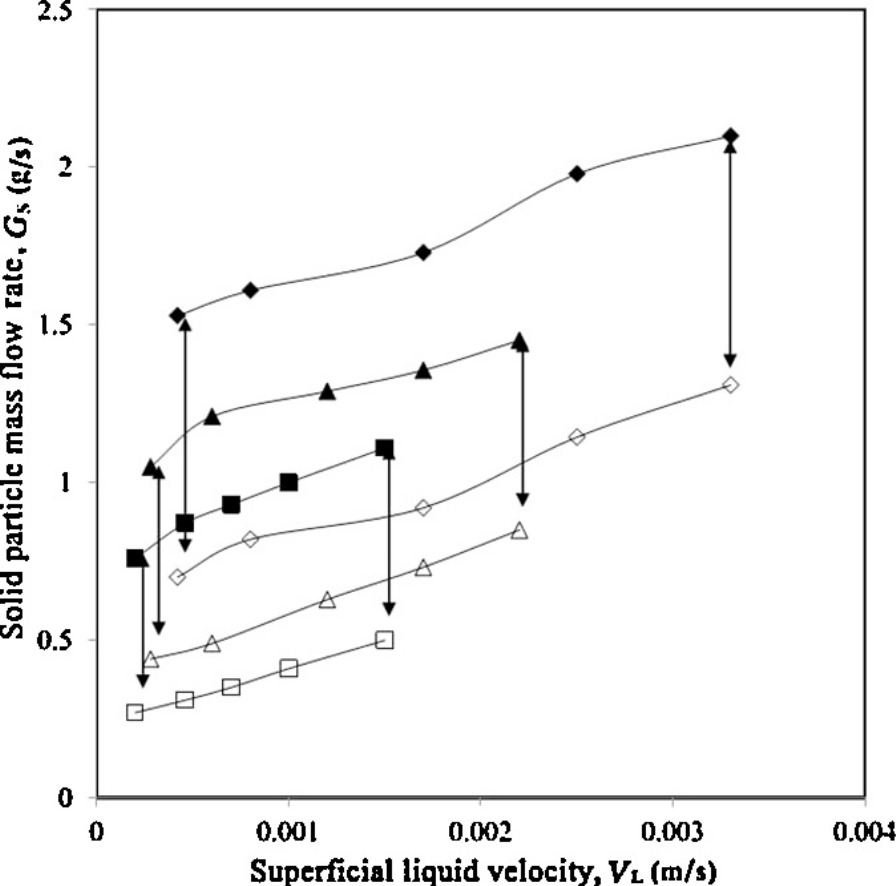

• The working of the SLCFB was demonstrated within the flooding and loading limits.

• The ratio of solid circulation rate to liquid velocity set criterion of scale-up of the system.

• Hydrostatic head predominantly contributed to the pressure drop in the multistage column.

• Multilayer perceptron neural network based model was employed for prediction of solid hold-up.

The present work proposes a novel radially cross-flow multistage solid–liquid circulating fluidized bed (SLCFB). The SLCFB primarily consists of a single multistage column (having an inner diameter of 100 mm and length of 1.40 m), which is divided into two sections wherein both the steps of utilization or loading (e.g., adsorption and catalytic reaction) and regeneration of the solid phase can be carried out simultaneously in continuous mode. The hydrodynamic characteristics were studied using ion exchange resin as the solid phase and water as the fluidizing medium. The loading and flooding states were determined for three particle sizes; i.e., 0.30, 0.42, and 0.61 mm. The effects of the superficial liquid velocity and solid feed rate on the solid hold-up were investigated under loading and flooding conditions. The solid hold-up increases with an increase in the solid feed rate and decreases with an increase in the superficial liquid velocity. An artificial-intelligence formalism, namely the multilayer perceptron neural network (MLPNN), was employed for the prediction of the solid hold-up. The input space of MLPNN-based model consists of four parameters, representing operating and system parameters of the proposed SLCFB. The developed MLPNN-based model has excellent prediction accuracy and generalization capability.