- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Ground pellet particles were denser and dried more slowly than ground chip particles.

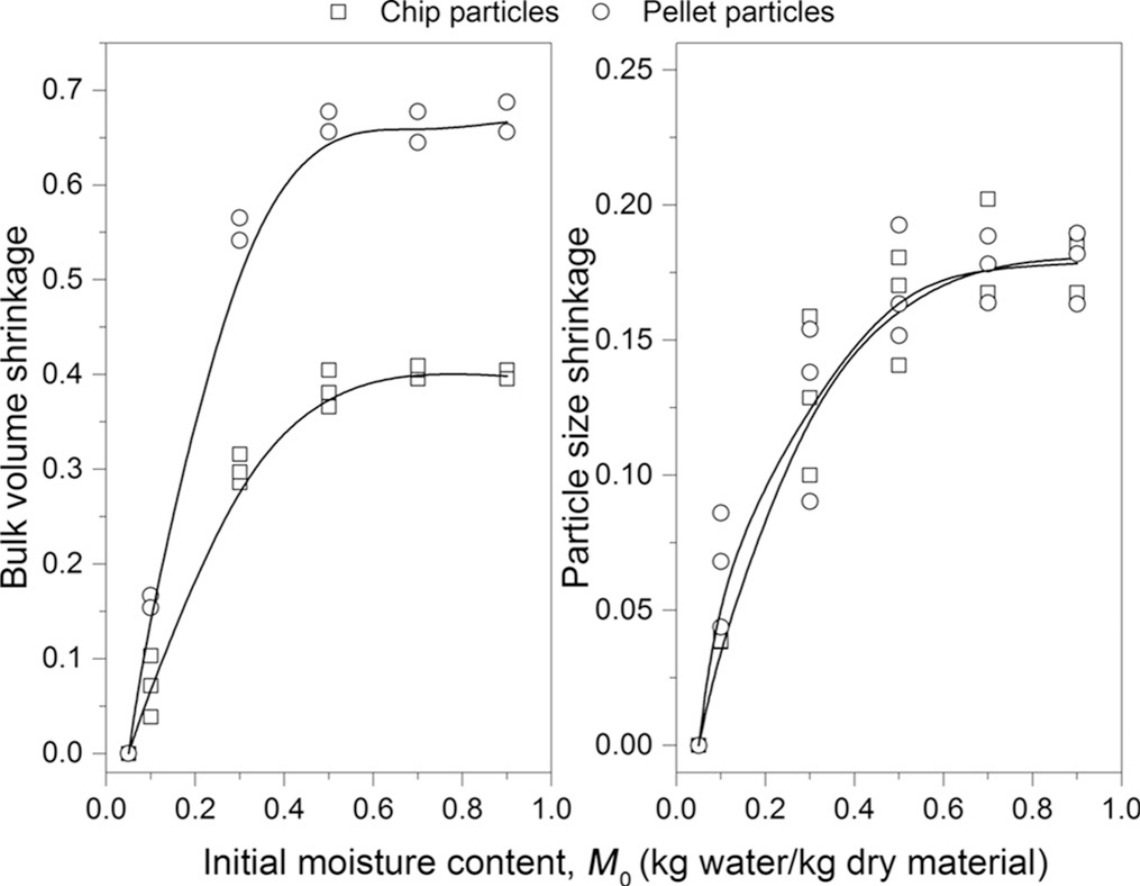

• Bulk of pellet particles shrank more than chip particles, despite their similar particle shrinkage.

• The variable radius drying model fitted better with experimental data than fixed radius model.

• The higher relative humidity of atmospheric air prolonged the drying process at 50 °C.

The effects of varying the mass and volume of ground chip and pellet particles on the particle drying rate were analyzed. Samples of whole pellets and chips were hammer milled using a 3.2 mm screen and the ground chip and pellet particles were found to have similar size distributions, although the pellet particles were denser and more spherical than the chip particles. Prior to drying, water was added to the particles to obtain 0.10, 0.30, 0.50, 0.70, and 0.90 moisture contents (on a dry mass basis). The moistened particles were subsequently dried in a constant temperature thin layer dryer set at 50, 100, 150, or 200 °C under dry pure nitrogen, dry compressed air, or atmospheric air. The chip and pellet particles exhibited similar degrees of shrinkage, but the pellet particles underwent a greater reduction in their bulk volume during drying. It appears that the more spherical pellet particles are prone to shrinkage in more than one direction, whereas the needle-like chip particle shrink only in one direction. A variable radius first order drying model was found to fit the experimental data better than a fixed radius model.