- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Overall heat transfer was measured in a mechanically fluidized reactor of silica sand.

• Enhancing bed aeration, via higher liquid injection, improved wall-to-bed transfer.

• Larger particles had higher heat transfer, opposing conventional fluidized beds.

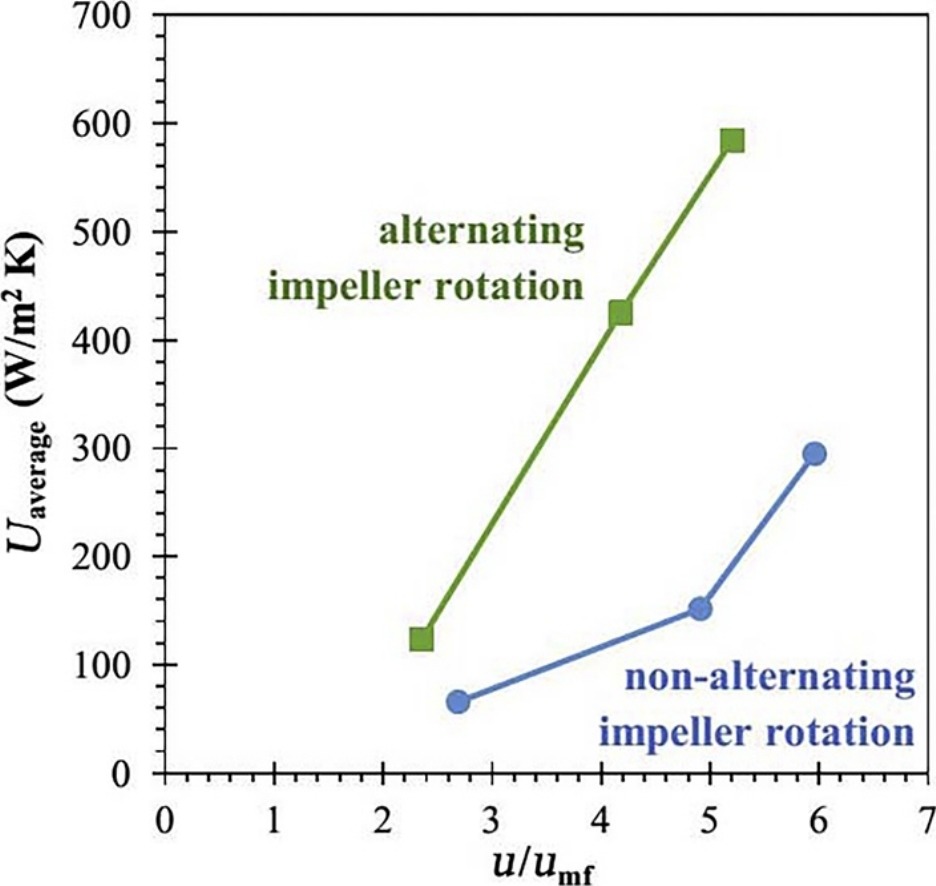

• Alternating the impeller rotation direction considerably increased heat transfer.

A mechanically fluidized reactor (MFR) is a novel and compact reactor used for biomass pyrolysis. Endothermic biomass pyrolysis requires heat provided from the wall of the MFR. Meanwhile, mixing with a vertical stirrer helps achieve effective heat transfer from the wall to the bed. Here, the heat transfer characteristics between the wall of a 1.0-L MFR and its bed of mechanically fluidized sand particles were studied. An induction heating system was used to heat the wall, while a vertical blade stirrer was used for mixing. Heat transfer measurements were carried out using silica sand particles, having three average Sauter mean diameters: 190, 300, and 600 μm. The overall wall-to-bed heat transfer coefficients were estimated using temperature measurements taken during continuous injection of water onto the fluidized bed. The overall heat transfer coefficient for bed temperatures of 500–700 °C increased as particle size increased or superficial velocity of the vaporized liquid increased. Effect of impeller rotation speed also was investigated. Typically, the overall heat transfer coefficient increased as rotation speed increased. The wall-to-bed heat transfer coefficients obtained in this study are comparable to estimates from traditional bubbling fluidized beds, even at vapor velocities below the minimum fluidization velocity.